|

| |

TM 5-4320-306-24

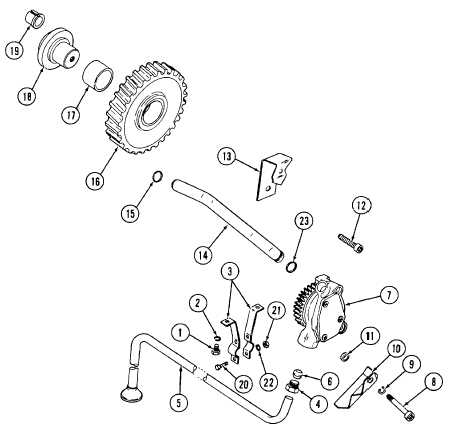

3-11. REPLACE/REPAIR OIL PUMP ASSEMBLY (Continued)

5 If yoke spring (13), shield (10), or pipe clips (3) are bent, reshape to approximate the original

functional shape. If the component cannot be restored to a functional configuration, or if the

mounting holes are elongated or torn, replace the component.

6 Buff a scratched or pitted journal (18) surface with emery cloth. If the pitting or scratches are

too deep to remove with fine emery cloth, the journal must be replaced.

7 Smooth chips or burrs from the bushing contacting hole of the journal with a fine file. If the

chips or burrs cannot be smoothed with a fine file, replace the journal.

8 A sheared or damaged bushing cannot be repaired; replace with new bushing.

9 Minor chips or pitting of idler gear (16) teeth can be smoothed with a fine file and crocus cloth

If the chips or pitting cannot be smoothed, the gear must be replaced

10 If the vertical clearance of the gear bushing exceeds 1.576 inches (40.030 mm), press the

damaged bushing from the gear and press in a new bushing.

3-55

|