|

| |

TM 5-4320-306-24

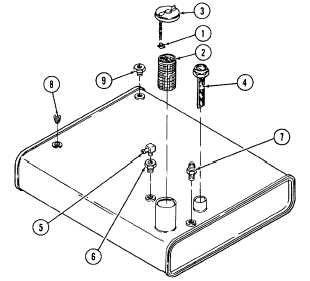

2-41 REPLACE/REPAIR FUEL TANK ASSEMBLY (Continued)

INSPECTION/REPAIR:

WARNING

Death or serious injury could occur if diesel fuel oil is not handled

carefully. Use in a well-ventilated area away from open flame,

arcing equipment, ignition sources, heaters, or excessive heat.

Always store fuel in proper, marked containers. DO NOT SMOKE.

Death or serious injury could occur if compressed air is directed

against the skin. Do not use compressed air for cleaning or drying

unless the pressure is/has been reduced to 30 psi (2.11 kgcm2) or

less. When working with compressed air always use chip guards,

eye protection, and other personal protective equipment.

1

Clean fuel mounting brackets and cushion mounts with diesel fuel oil and dry with compressed air. Inspect for minor

rust, corrosion, or other damage. Replace mounting brackets if severely rusted or damaged Inspect for worn or

missing cushion mounts. Replace cushion mounts if damaged or missing.

2

Clean outside of fuel tank assembly and remove sediment with diesel fuel oil. Dry with compressed air. Inspect for

minor rust, corrosion, or broken welds. Replace if damaged.

3

Clean fuel tank cap and fuel filler screen with diesel fuel oil and dry with compressed air. Inspect for minor rust or

corrosion. Make sure fuel tank cap vent is open. Replace if damaged.

4

Check fuel gage for damage. Replace if damaged.

5

Check pipe plug, 90-degree elbow, male connector, and bushings for rust, corrosion, stripped threads, or other

damage. Replace any damaged fittings.

ASSEMBLY:

1

Install bushing (9).

2

Install plug (8).

3

Install male connector (7).

4

Install 90-degree elbow (5) and bushing (6).

5

Install fuel gage (4).

6

Engage connector clip (1) into fuel filler screen (2)

and install. Be sure fuel tank cap vent is in open

position.

2-144

|