|

| |

TM 5-4320-305-24

4-13.

REPLACE/REPAIR CRANKCASE ASSEMBLY (Continued)

15

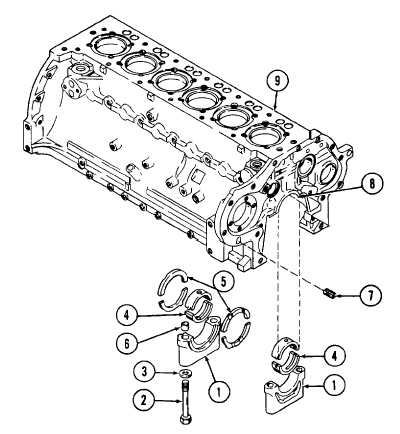

Check and match-mark the main bearings and caps according to paragraph 4-12.

16

Inspect crankcase bearing caps (8). If stripped, worn, cracked, or damaged, replace crankcase (9).

NOTE

The upper bearing cap is an integral part of the crankcase. If an upper bearing cap is damaged,

the crankcase must be replaced.

17

Inspect bearing caps (1), and replace for excessive wear, overheating, distortion, cracking, high spots, or other

damage.

18

Inspect main bearings (4) for excessive wear, overheating, distortion, cracking, or other damage. Replace worn or

damaged bearings.

19

Measure main bearing (4) wall thickness. The normal wall thickness should be between 0.0876 to 0.0878 inch

(2.224 to 2.229 mm). If measurement is outside of tolerance limit, replace bearing.

4-110

|