|

| |

TM 5-4320-305-24

4-13. REPLACE/REPAIR CRANKCASE ASSEMBLY (Continued)

CLEANING/INSPECTION:

WARNING

Death or serious injury could occur if diesel fuel oil is not handled carefully. Use

in a well-ventilated area away from open flame, arcing equipment, ignition

sources, heaters, or excessive heat. Always store fuel in proper, marked

containers. DO NOT SMOKE.

Death or serious injury could occur if compressed air is directed against the skin.

Do not use compressed air for cleaning or drying unless the pressure is/has been

reduced to 30 psi (2.11 kgcm2) or less. When working with compressed air always

use chip guards, eye protection, and other personal protective equipment.

Live steam used for cleaning shall not exceed 100 psi (690 kPa). Use goggles or

face shield for eye protection. Do not direct live steam against skin.

1

Clean crankcase thoroughly with live steam. Clean all exterior and interior openings and surfaces. Be especially

careful to clean all oil passages to make sure they are open. Use a small and/or large wire bristle brush where

necessary to remove carbon or other deposits from openings and surfaces. Use diesel fuel oil as necessary to

soften and remove carbon or hardened oil deposits. Dry with compressed air.

2

Thoroughly inspect crankcase for any cracks, discoloration, distortion, rust, corrosion, or other damage. Use

MIL-1-

6868 magnetic particle inspection to detect cracks. If crankcase is cracked, distorted, overheated, seriously rusted

or corroded on machined surfaces, or exhibits other serious damage, replace crankcase.

3

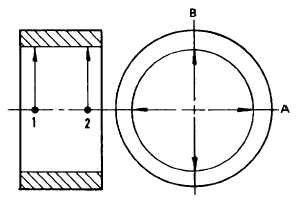

Make sure camshaft bushing (1) is seated properly in crankcase. Inspect for damage or excessive wear. Measure

bushing bore with micrometer at points 1 and 2 and along axes A and B. Bore measurement should be 1.889 to

1.8911 inches (47.98 to 48.034 mm). If measurement is outside these tolerance limits, replace bushing.

4-106

|