|

| |

TM 5-4320-305-24

4-11. REPLACE/REPAIR CONNECTING ROD ASSEMBLY (Continued)

NOTE

Clean rust preventive from replacement connecting rod. Also make sure the bearing cap is

thoroughly cleaned to prevent trapped contaminants from adversely affecting the bearing shells.

9

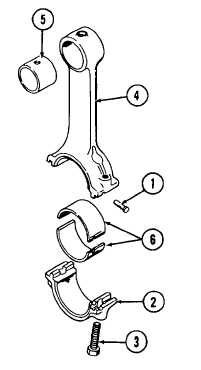

Temporarily reassemble dowel pin (1) and bearing

cap (2) with big-end bolts (3) onto match-marked

connecting rod (4). Tighten bolts to 22. 13 ft-lb (30

N-m) torque. Using a torque gage, retighten bolts an

additional 60 degrees, then an additional 30 degrees.

10

Measure width of connecting rod (4) with micrometer.

Measurement should be 1.3960 to 1.3984 inches (35.

46 to 35. 52 mm). If measurement is outside

specified limits, replace connecting rod.

11

Measure connecting rod bore with inside micrometer.

Measurement should be 2.6771 to 2.6779 inches

(68.0 to 68. 019 mm). If measurement is outside

specified limits, replace connecting rod (4) including

bearing cap (2), small-end bushing (5), bearing shells

(6), and big-end bolts (3).

12

Inspect bearing shells.

a.

Inspect upper and lower bearing shells for

excessive

wear,

scoring,

pitting,

flaking,

etching, and signs of overheating.

b.

Inspect bearing shell backs for bright spots

(bearing moving in bearing shells).

c.

Measure bearing shell width. Measurement

should be 1.0157 to 1.0236 inches (25.8 to 26.0

mm). If measurement is outside specified

limits, replace bearing shells.

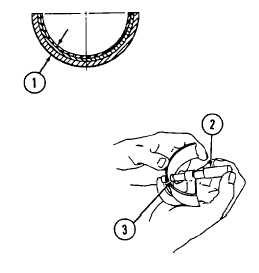

d.

Measure bearing shell wall thickness (1) with a

micrometer (2) and ball attachment (3). The

minimum thickness of a worn standard bearing

shell

is

0.0778

inch

(1.976

mm).

If

measurement is below specified limit, replace

bearing shells.

4-86

|