|

| |

TM 5-4320-305-24

4-6. REPAIR CYLINDER HEAD ASSEMBLY AND ROCKER ARMS (Continued)

4

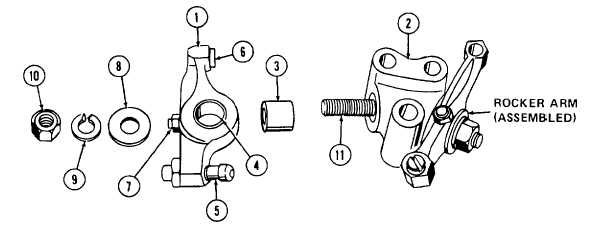

Clean rocker arm (.1), rocker bracket (2), rocker fulcrum (3), bearing bushing (4), adjusting screw (5), thrust pad (6),

nut and oil nozzle (7), washer (8), lockwasher (9), and nut (10) with diesel fuel oil.

5

Use a small wire to clean drilled oil passages in rocker arms (1), oil nozzle (7), and bearing bushing (4). Dry parts

with low pressure compressed air.

6

Inspect rocker bracket (2) and stud (11) for excessive wear or other damage. Inspect rocker arm (1), rocker fulcrum

(3), and bearing bushing (4) bores for wear.

7

Inspect shaft-to-bushing clearance for excessive wear.

8

Inspect bearing bushing (4) exterior surface and oil nozzle (7) for excessive wear.

9

Inspect rocker arms (1), adjusting screw (5) (pushrod contact surface), and thrust pads (6) (valve contact surfaces)

for excessive wear.

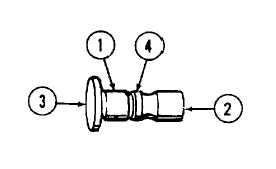

10 Clean tappets (1), tappet head (2), tappet seat (3),

and oil hole (4) thoroughly with diesel fuel oil and

dry with low pressure compressed air. Inspect for

damage, wear, or clogged oil hole.

4-42

|