|

| |

TM 5-4320-305-24

4-4. REPAIR INJECTION PUMP (Continued)

i.

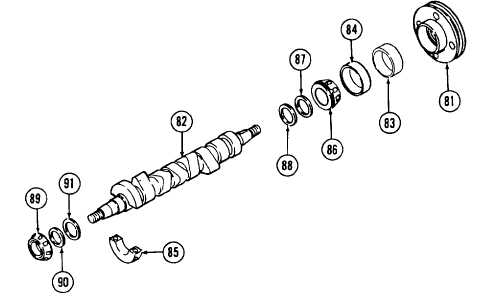

Install protective sleeve KDEP 2874 onto bearing cap (81). Press bearing cap from camshaft (82) using

mechanical puller. Remove protective sleeve.

j.

Remove and discard oil seal (83). Remove bearing cone (86) from drive end of camshaft using mechanical

puller.

k.

If reading recorded in step d is less than 0.0008 inch (0.020 mm), remove shim (87). If end play is more than

0.0024 inch (0.061 mm), add a shim.

I.

Press new oil seal (83) into bearing cap (81).

CAUTION

Press only on inner race of bearing cone during installation to prevent damage to

bearing.

m. Press bearing cone (86) onto camshaft. Press bearing cap (81) onto camshaft.

n. Install assembled bearing cap and camshaft into housing.

o. Install two screws (41) and two lockwashers (42). Torque screws to 61 to 78 in-b (6.9 to 8.8 N.m).

p. Install two spacers (45), timing indicator (44), and two screws (43). Torque screws to 61 to 78 in-lb (6.9 to 8.8 N

m).

q. Repeat steps a through p to recheck camshaft end play.

4-28

|