|

| |

TM 5-4320-304-14

TM 08922A-14/1

5-5. REPLACE ENGINE ASSEMBLY

This task covers:

a. Removal

b. Installation

INITIAL SETUP

Tools

General Safety Instructions

Shop equipment, automotive maintenance

and repair, common no. 1

Hoisting equipment shall be used only by

authorized personnel.

Equipment

Condition

Para

Condition Description

4-14

Pump case assembly removed.

4-15

Air filter assembly removed.

REMOVAL:

Death or serious injury could occur if unauthorized or unnec-

essary personnel are in the hoisting area. Permit only person-

nel actually engaged in the hoisting operation to be near the

unit and hoisting equipment. All instructions for the hoisting

operations must come from one authorized person.

Death or serious injury to personnel or damage to equipment

could occur from improper hoisting. Hoist the load slowly to

avoid tearing out lifting strap, slipping slings, or load shift. Do

not jerk the load or swing it from side-to-side when hoisting.

This places additional stress on hoisting components which

can cause failure and loss of load. Be sure hoisting equipment

is on solid footing and is suitable for the size of the load.

Watch boom angle and overhead clearance when hoisting.

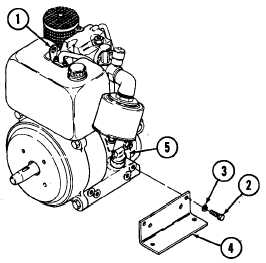

1

2

3

4

5-6

Engine will be damaged if set on

cover at bottom of engine. Pro-

vide adequate blocking to support

engine after removal.

Position a suitable lifting device over engine assembly.

Attach to lifting strap (1).

Put tension on slings. Make sure engine is properly

supported.

Remove four hex screws (2) and four spring washers

(3) from each engine bracket (4). Remove engine

assembly (5).

Lift engine assembly (5) and lower onto blocks on

a stable, level work platform.

|