|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4320-273-14

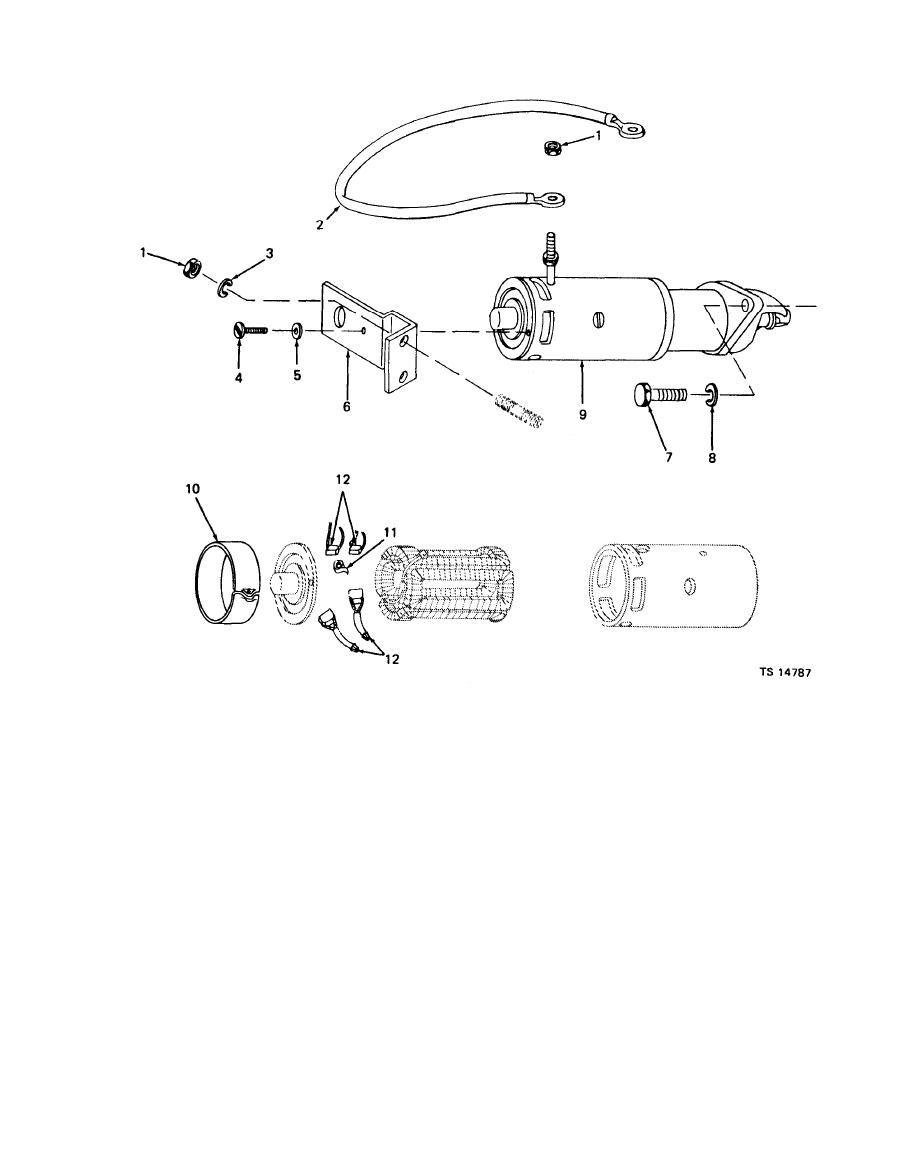

1. Nut

7. Capscrew

2. Cable

8. Lockwasher

3. Lockwasher

9. Starting motor

10. Cover band

4. Machine screw

11. Brush spring set

5. Flat washer

12. Brush set

6. Support bracket

Table 4-2. Troubleshooting -- Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE -- Continued

Remove the nuts (1) and lockwashers (3) that secure the support bracket (6) to the engine. Remove the

machine screw (4) and the flat washer (5) that mount the starting motor to the support bracket (6). Remove

the support bracket.

Remove the three capscrews (7) and lockwashers (8) that secure the starting motor (9) to the flywheel

housing.

Pull the starting motor straight out to remove from engine. Inspect starter Bendix for operation and starter

for worn brushes.

Replace brushes if they are worn more than 3/8 inch (0.95 cm) as follows:

Loosen cover band screw and slide the cover band (10) from the brush accees openings in the starter frame.

Unhook the spring set (11) retaining each brush and hold it out of the way of the brush. Holding the brush

set (12) by the leads carefully remove brush through the access opening. Remove brush only far enough to

disconnect brush leads from field leads. Repeat this procedure for each brush.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |