|

|||

|

|

|||

|

Page Title:

Fuel System. |

|

||

| ||||||||||

|

|

TM 5-4320-273-14

Operator/crew maintenance of the fuel system con-

sists primarily of the following procedures:

a. Servicing the Air Cleaner.

(1) You should service the air cleaner any time

the air restriction indicator shows red in the sight

area.

(2) Loosen the clamp assembly (1, fig. 3-4) and

remove the dust cap (2) and vacuator valve (3).

Remove the baffle (4) and empty the dust cap and

vacuator valve.

(3) Remove the wing nut (5), and remove the

filter element (6). The element can be dry-cleaned

q

with compressed air, directing the air stream from

the inside out. If time permits, you can also wash the

element with water and, upon completion, air-dry it.

CAUTION

Do not use gasoline, kerosene, or

solvent to clean element; do not oil

element.

(4) Replace the element if it is damaged.

(a) Install

filter element (6, fig. 3-4) in body

and secure with wing nut (5). Install baffle (4) and

vacuator valve (3) on dust cap (2).

(b) Install dust cap (2) on air cleaner body and

secure with clamp assembly (l).

b. Servicing Fuel Tank, Lines, and Fittings. Main-

tenance of the fuel tank, lines, and fittings is nor-

mally confined to such services as filling the tank

with fuel and tightening loose fittings.

(1) Drain the fuel tank by removing the plug and

draining the fuel into a suitable container. Clean the

strainer with a soft-bristled brush to remove em-

bedded material.

(2) Inspect the fuel tank and lines for leaks,

cracks, dents, damaged threads, and broken weld-

ments. You should report any damage to

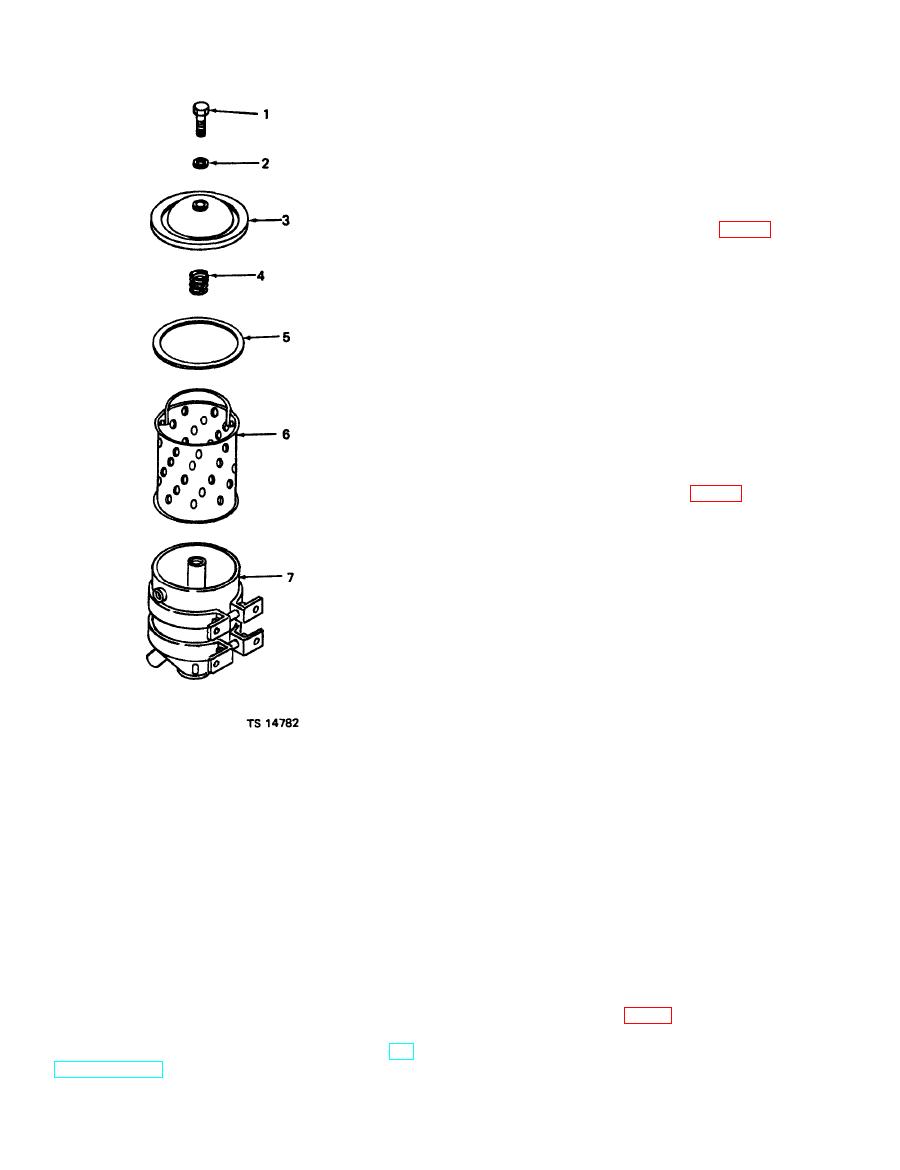

1. Shoulder bolt 5. Gasket

2. Flat washer

6. Filter element

organisational maintenance.

3. Cover

7. Body

(3) Check for clogged fuel lines by loosening the

4. Spring

nut connecting the fuel line to the carburetor. If the

Figure 3-5. Oil filter.

line is open, fuel will drip out at the loosened nut. If

the fuel line is clogged, you should report it to organi-

(2) You can now lift the filter element (6) from the

zational maintenance.

filter body (7). Discard the filter element.

(4) Insert the drain plug and fill the fuel tank to

(3) Wipe the interior of the filter body with a

clean, dry cloth and position a new filter element (6)

the proper level.

c. Servicing the Fuel Strainer. If you observe

in the filter body (7).

moisture or other contaminants in the glass bowl of

(4) Install the gasket (5), spring (4), and cover (3)

the fuel strainer, service the strainer as follows

on the filter body (7). Position the flat washer (2) on

the shoulder bolt (l). Tighten the shoulder bolt to

(1) Turn the fuel source selector valve to OFF

position.

secure the cover.

(2) Loosen the nut (1, fig. 3-6) on the bail assem-

(5) After installing a new filter element, check

bly (2) and swing the bail aside to remove the glass

the oil level dipstick. Add oil if you find the level

fuel bowl (3) and gasket (4). Empty the contents of

below the full mark, but do not overfill. Refer to LO

5-4320-273-12 for recommended oil.

the bowl and wipe it dry with a clean cloth.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |