|

|||

|

|

|||

|

Page Title:

CHAPTER 4. REPAIR OF CENTRIFUGAL PUMP |

|

||

| ||||||||||

|

|

REPAIR OF CENTRIFUGAL PUMP

are in constant contact to stop seepage of fluid through

4-1. Description

the seal. Both parts are sealed to their associated parts

This self-priming centrifugal pump is designed to

with petroleum-resistant Buna N rubber parts.

pump flammable liquids at relatively high discharge

heads. It uses a closed-type impeller which is mounted

directly on the extended engine crankshaft. It contains

no bearings since the crankshaft is adequately sup-

ported by the engine bearings. A face seal prevents

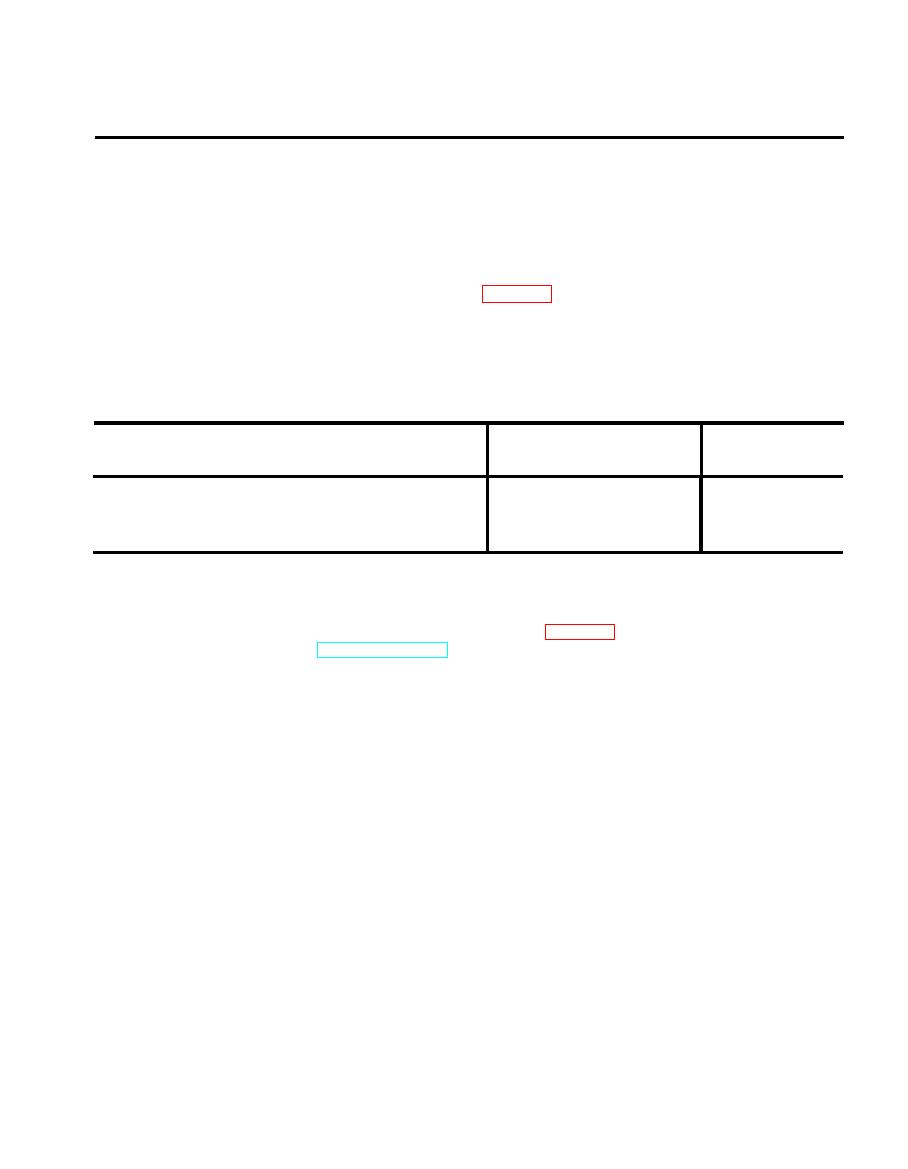

Refer to the table to help you determine if parts

leakage around the shaft. The seal consists of a Ni-

replacement is required or if continued serviceability

Resist stationary member and a spring-loaded carbon

of the parts is possible.

rotating member. The highly finished mating surfaces

Normal clearances

Maximum allowable

(in inches)

Component points of

Maximum

clearance

Minimum

measurement

0.052

0.092

0.042

Impeller-to-wear ring clearance

5.107

Wear ring internal diameter

5.015

Impeller external diameter at wear ring surface

I

I

-

.

for instructions. Disassemble the centrifugal pump as

a. Removal and Disassembly. Remove the suction

shown in figure 4-1.

piping assembly, discharge piping assembly, and the

instrument control panel. Refer to TM 5-4320-272-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |