|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

when you r e a s s e m b l e the valve. Tighten the

(2) To adjust the check valve for automatic

packing nut tightly enough to prevent leaking, but

closing, rotate the spring bracket (14) coun-

not so tightly that it prevents free rotation of the

terclockwise so that the spring pulls the check valve

shaft.

closed after you operate the lever manually to fully

( 2 ) Adjust the check valve for automatic

open the valve.

closing or for manual closing as directed in sub-

(3) To adjust the check valve so that it

paragraph a above.

remains open when set, rotate the spring bracket

(3) After you install the valve, start the pump

( 1 4 ) clockwise so that an overcentering action

and check that the valve opens and closes properly

o c c u r s as the valve is fully opened, requiring

and t h a t t h e r e a r e n o l e a k s . C o r r e c t a n y

manual pressure on the lever to close it.

deficiencies.

(4) After you have made the required ad-

justment, tighten the cap screws (10 and 11) to lock

4 - 4 5 . Air Eliminator

the spring bracket in position.

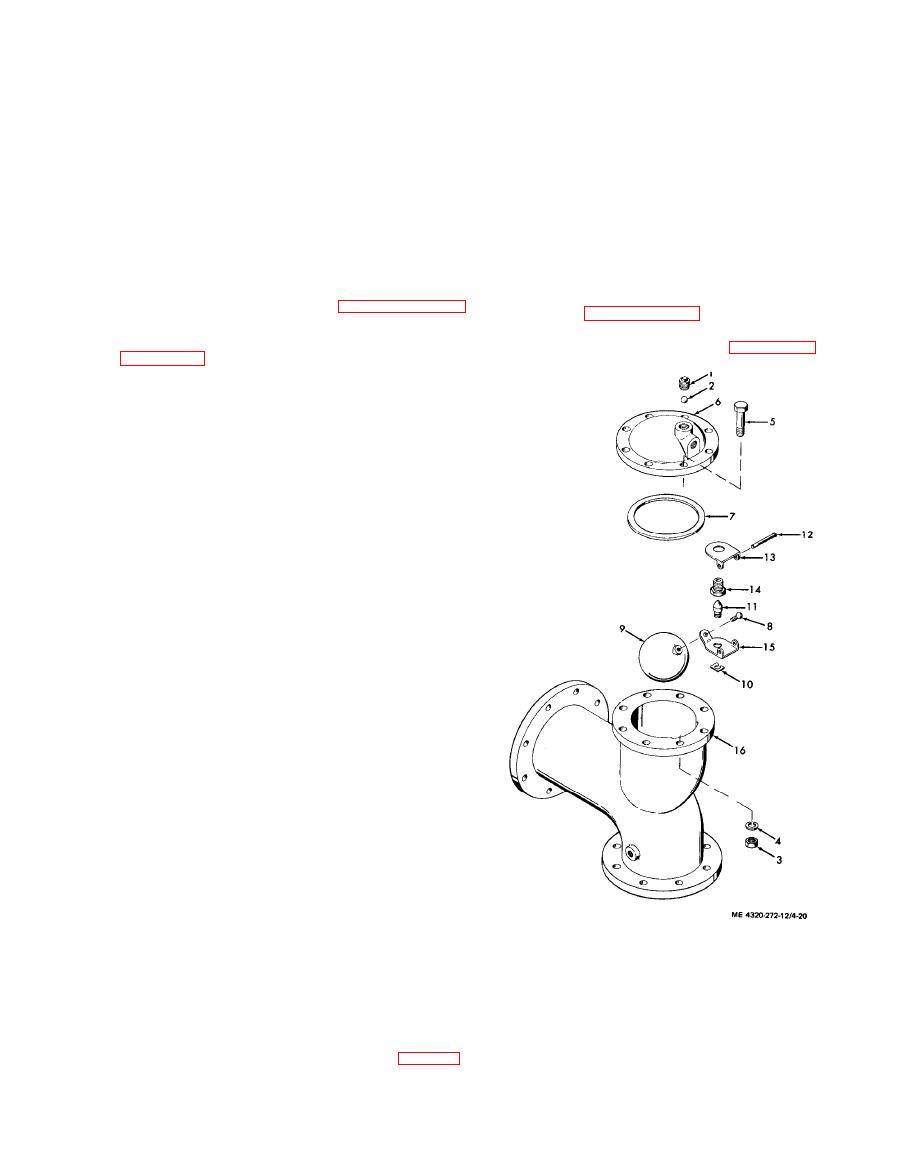

a. Removal and Disassembly. R e m o v e t h e a i r

b. Removal and Disassembly. R e m o v e t h e

eliminator from the discharge piping assembly as

check valve as indicated in paragraph 4-42.

described in paragraph 4-42. Disassemble the air

Disassemble the check valve following the sequence

eliminator following the sequence of index numbers

of index numbers assigned to the exploded view in

assigned to the exploded view in figure 4-20.

(1) To remove the valve shaft (21), you must

remove the setscrews (22) and the packing nut

(20), and insert a soft drift through the hole from

which the plug (19) was removed. Tap on the end

of the drift to dislodge the shaft.

(2) You will have to use a pointed or hooked

instrument to dislodge the packing rings (25) from

the body (28).

( 3 ) Do not remove the stud (27) from the

valve body (28) unless they are damaged or loose.

c. Cleaning and Inspection.

WARNING

Clean all parts in a well-ventilated area.

Avoid inhalation of solvent fumes and

prolonged exposure of the skin to

c l e a n i n g solvent. Wash exposed skin

thoroughly.

( 1 ) Discard and replace the packing rings

( 2 5 ) . Clean all remaining parts with cleaning

solvent (fed. spec. P-D-680); dry thoroughly.

( 2 ) Inspect the valve disc (8) for cracks,

distortion, or other damage. You can remove minor

burrs on the seating surface with fine emery cloth.

(3) Inspect valve body (28) for cracks,

damaged threads, damaged flanges, worn shaft

b o r e , and damaged seating surface. You can

remove minor nicks or burrs from the valve seats if

necessary. Clean up the seats evenly so that they

permit proper seating of the valve discs.

( 4 ) Inspect the shaft (21) for wear of the

bearing surfaces. Replace if you see any indications

of wear.

(5) Inspect all other parts for cracks,

distortion, a n d damaged threads; replace any

9. Float

1. Pipe plug

damaged parts.

10. Retainer

2. Ball

d. Reassembly and Installation. R e a s s e m b l y

11. Valve

3. Nut

and installation is essentially the reverse of the

12. Pin

4. Lock washer

disassembly and removal sequence. Refer to figure

13. Clip

5. Cap screw

4 - 1 9 and 4-17. Pay particular attention to the

14. Valve seat

6. Cover

7. Gasket

15. Lever

following:

8. Screw

16. Body

( 1 ) Use new packing rings (25, fig. 4-19)

view.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |