|

|||

|

|

|||

|

Page Title:

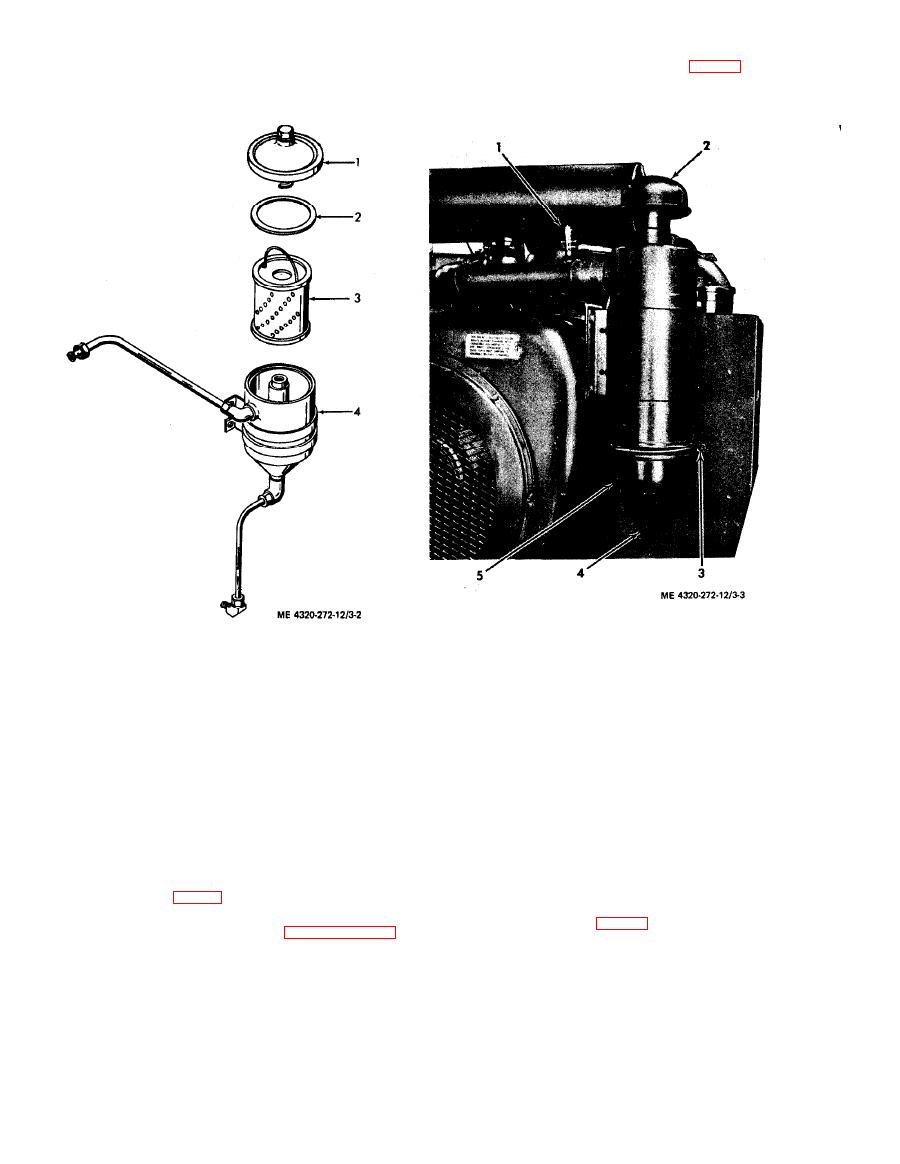

Figure 3-2. Oil filter replacement. |

|

||

| ||||||||||

|

|

open the lips of the vacuator valve (4, fig. 3-3) to

release the collected dust. This will lengthen the life

of the main filter.

1. Air restriction indicator

4. Vacuator valve

2. Stack cap

5. Dust Cup

1. Cover

3. Element

3. Clamp

4. Body and lines

2. Gasket

(2) Daily, unless experience indicates that it

(2) You can now grasp the filter element (3)

can be done less frequently, loosen the clamp (3)

by its handle and lift it from the filter housing.

and remove the dust cup. Remove the baffle from

Discard the filter element.

the cup and empty the dust. When reinstalling the

(3) Wipe the interior of the filter housing with

baffle in the cup, you must make sure the baffle is

a clean, dry cloth.

properly seated. Check the dust cup sealing edge

(4) Position a new filter element in the filter

for damage. Check the dust cup gasket. Reinstall

housing.

the dust cup and make sure it is properly positioned

(5) Install the cover and gasket on the filter

on the air cleaner body.

and tighten the hex screw at the top of the filter to

(3) Weekly, or any time the restriction in-

secure the cover (1).

dicator shows red in the sight area, service the air

(6) After installing a new filter, check the oil

cleaner element. To remove the element, remove

level dipstick (4, fig. 3-1). It must be up to the full

the cup and baffle as directed in step (2), above.

mark. Add oil if you find the level low, but do not

Remove the wing nut (5, fig. 3-4) and remove the

overfill. Use oil recommended in paragraph 3-3.

element (6). The element can be dry-cleaned with

compressed air. Direct the air stream from the

inside out. If you prefer, you can wash the air

Operator / crew maintenance of the fuel system

cleaner element with soap and water. Dry it with

consists primarily of the following procedures:

circulating air at less than 180oF. Replace element

a. Servicing Air Cleaner.

if any damage is visible. Reassemble the air cleaner.

(1) Daily, or several times a day under ex-

tremely dusty conditions, with the engine stopped,

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |