|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

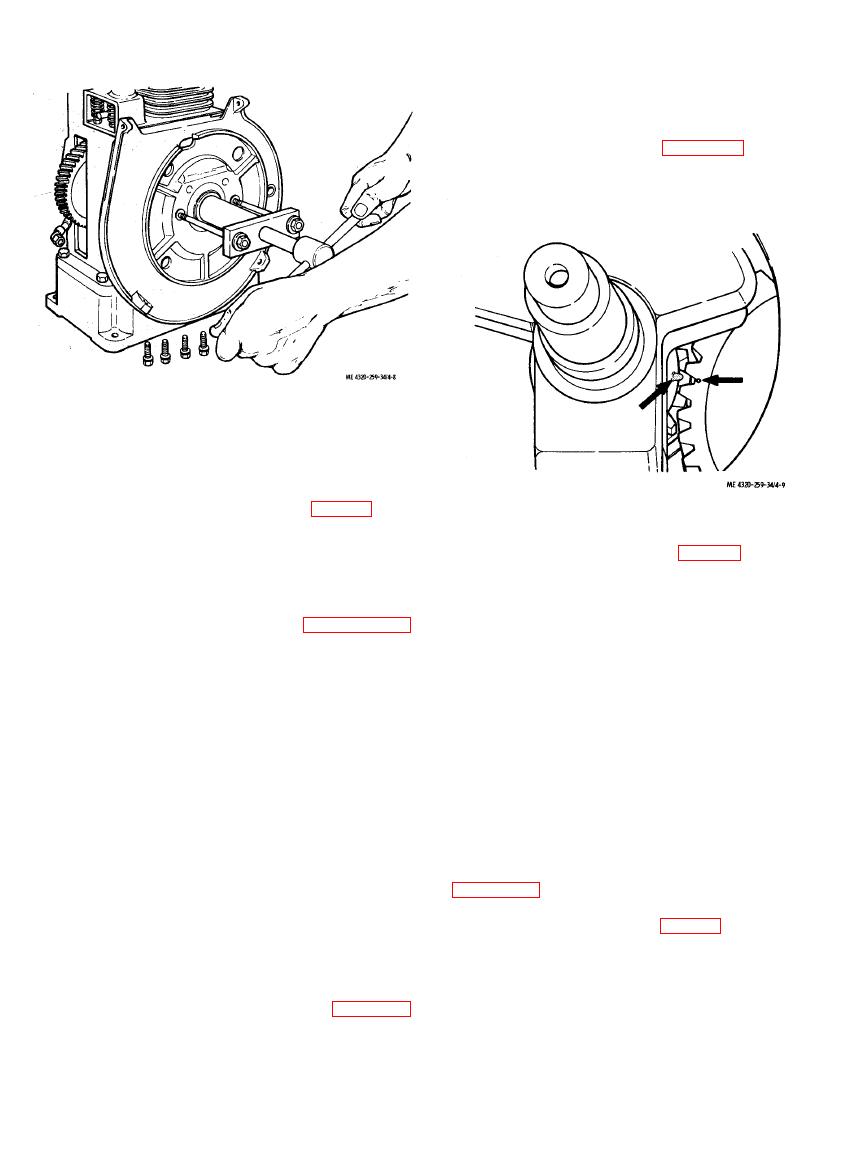

b. Place

the cylinder block on an arbor press and

insert the untapered end of the crankshaft into the

bore of the bearing in the cylinder block. Aline the

timing mark on the tooth of the gear section of the

crankshaft with the timing mark (dot) on the

cam shaft gear as shown in figure 4-9. With the

marks alined, press in the crankshaft until it is fully

seated on the ball bearing. Recheck timing marks

to assure that they are alined.

f. Remove the cylinder block. It may be

necessary to use a press to dislodge the crankshaft.

Take care to prevent damage to the threaded

crankshaft ends.

remain with the shaft or may remain in the bearing

seats of the cylinder block or bearing plate. Press

out the seals (8 and 11) and bearings (9 and 12).

bearing plate (5) so that the shielded side will face

out when the bearing plate is installed on the

engine. Make sure the bearing is pressed squarely

a. Discard the seals and gaskets.

into the bearing plate or correct crankshaft end

b. Clean bearings as directed in paragraph 2-7.

play will not be registered.

c. Clean all other parts with an approved

d. Position the bearing plate (5) on the cylinder

cleaning solvent; dry thoroughly.

block, using one 0.020-inch and one 0.010-inch

gasket. Install the thicker gasket next to the

balls, excessive looseness between races and balls,

cylinder block. Carefully press the bearing plate

rough, binding, or catching operation, and other

into position on the cylinder block. Secure the

damage; replace damaged ball bearings.

bearing plate with four cap screws (2), lock washers

e. Inspect the crankshaft for damaged threads,

(3), and flat washers (4). Tighten the cap screws

worn or broken gear teeth, scored or worn crank-

pin, misalinement, a n d other damage. The

evenly and alternately to prevent distorting the

bearing plate.

minimum allowable diameter of the crankpin

e. Check the crankshaft end play by measuring

journal is 0.9355 inch. The journal width shall be

with a feeler gage. Measure between the inner race

at least 0.875 so that connecting rod side play does

of the ball bearing pressed into the cylinder block

not exceed 0.016 inch. Check the bearing seat

and the shoulder on the crankshaft as shown in

surface for scoring or damage. Remove any burrs

figure 4-10. End play shall be 0.0038 to 0.0228

from the crankshaft with a fine stone. Replace the

inch. If end play is not within the required limits,

crankshaft if damaged.

remove the bearing plate (5, fig. 4-7) and add or

f. Inspect the bearing plate for cracks, distor-

remove gaskets ( 6 ) . The addition of gasket

tion, damaged bearing bore, and damaged threads;

thickness will increase end play. Subtraction of

replace a damaged bearing plate.

gaskets will decrease end play.

Reassemble the crankshaft as shown in figure 4-7,

items 2 through 11. Note the following:

a. Press the rear main bearing (12) into the

bearing seat of the cylinder block so that the

bearing shield faces out of the block.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |