|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

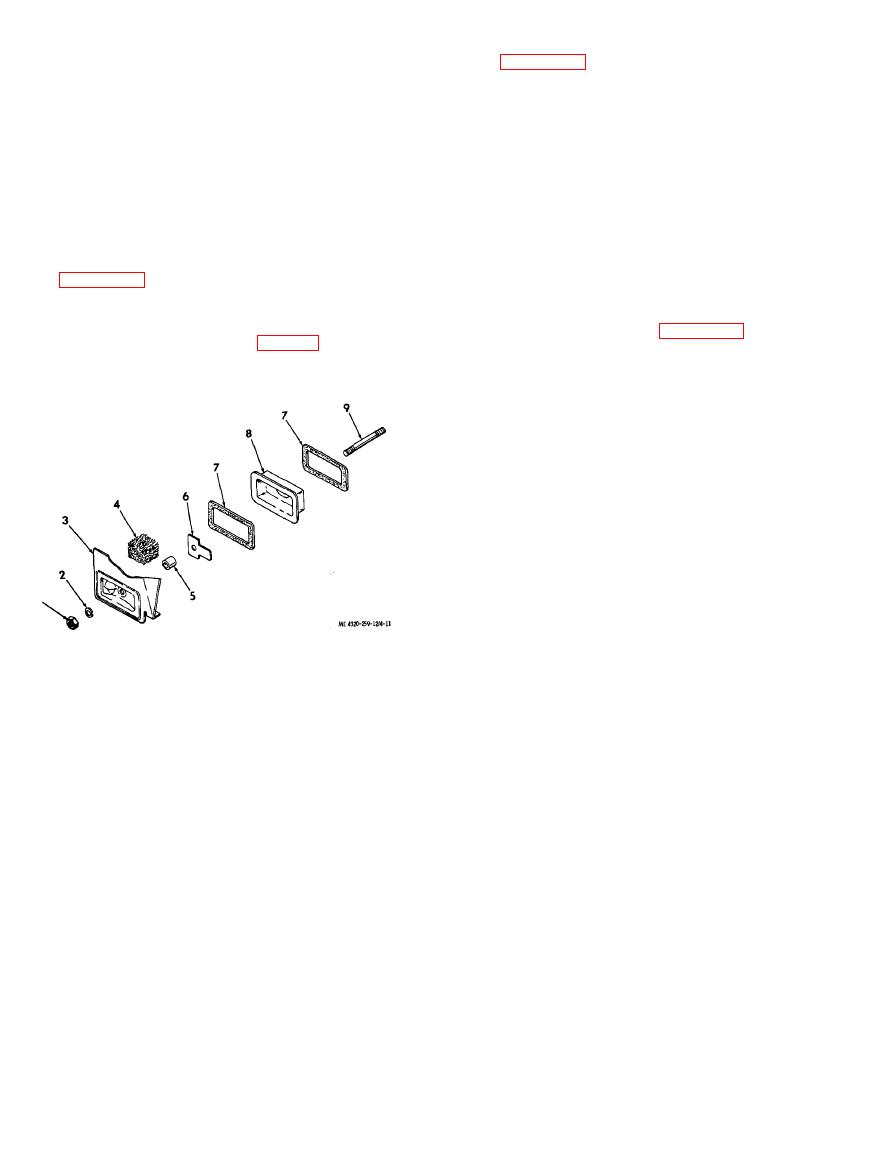

(2) Disassemble the breather assembly as

b. Cleaning and Inspection.

shown in figure 4-11.

(1) Clean all parts with an approved cleaning

b. Cleaning and Inspection.

solvent. Wirebrush the muffler to remove all rust

(1) Clean all parts with an approved cleaning

and corrosion.

solvent. Shake the filter free of solvent. Wipe all

(2) Inspect the muffler for cracks, holes, thin

other parts dry.

spots, and other damage that could affect its noise-

(2) Inspect the filter for matting, clogging,

reducing or spark-retarding characteristics.

and deterioration; replace a damaged filter.

Replace a damaged muffler.

(3) Inspect the reed and breather plate for

(3) Inspect all other parts for cracks, rusting,

cracks and distortion. The reed must make a good

signs of deterioration, and other damage; replace

seal against its seat on the breather plate. Replace

damaged parts.

dam aged parts.

c. Reassembly and Installation. Reassemble

( 4 ) Inspect all other parts for cracks,

and install the muffler and related parts as shown

distortion, and other damage; replace damaged

in figure 4-10.

parts.

a. Removal.

the engine crankcase as shown in figure 4-11. Make

(1) Remove the nut (1, fig. 4-11) and lock

sure all sealing surfaces are tight to prevent the

washer (2); remove the entire breather assembly

entry of dirt into the engine.

from the engine crankcase.

1.

Nut

2.

Lock washer

3.

Cover

4.

Filter

5.

Seal

6.

Breather reed

7.

Gasket

8.

Breather plate

9.

Stud

Section XI. MAINTENANCE OF PUMP ACCESSORIES

The hose ends are identical to those used on the

4-26. Description

suction hose.

a. One 10 foot, wire-reinforced, rigid-walled

c. Two 1 inch discharge nozzles are pro-

suction hose is provided with the pumping

vided with the pumping assembly. The nozzles

assembly. One end of the hose is fitted with a male

are the non-automatic type so that discharge stops

quick-disconnect coupling and the opposite end

immediately when the operating lever is released.

uses a female quick-disconnect coupling. One plug

The nozzles are provided with quick-disconnect

and one cap are provided to prevent the entry of

couplings, and dust plugs are provided to prevent

dirt into the hose.

the entry of dirt. A screen strainer in the spout

b. Two 50 foot, collapsible-walled discharge

prevents foreign particles from entering the fuel

hoses are provided with the pumping assembly.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |