|

|||

|

|

|||

|

Page Title:

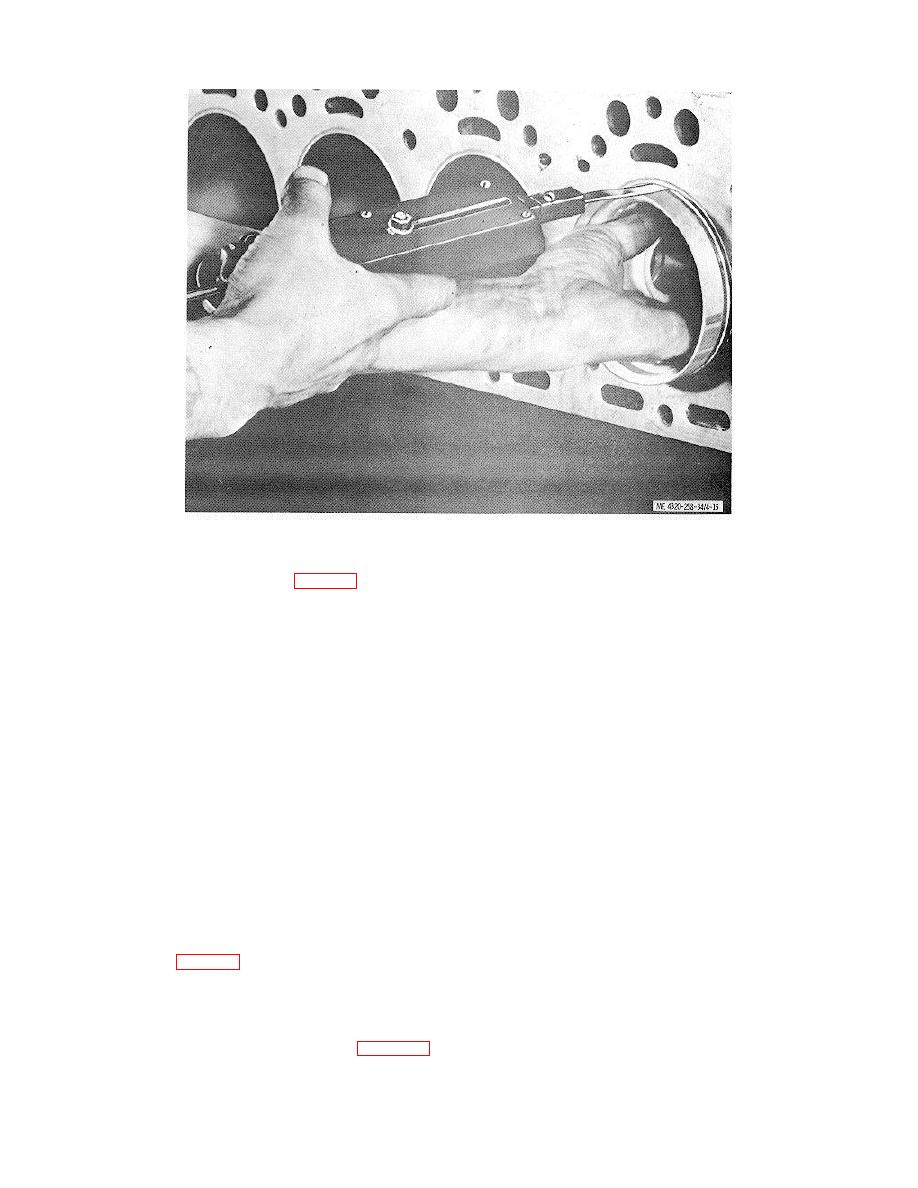

Figure 4-15. Checking piston fit in cylinder bore. |

|

||

| ||||||||||

|

|

TM 5-4320-258-34

Figure 4-15. Checking piston fit in cylinder bore.

(6) Install the oil ring in the bottom ring

(2) If new pistons (18, fig. 4-14) and piston

groove of each piston as follows:

pins (16) are being used, press a new sleeve bearing

(a) Place stainless steel expander

(19) into each connecting rod (20). Ream and hone the

sleeve bearings to 0.8595- to 0.8597-inch diameter.

spacer in groove with ends butted.

(b) Install steel segment on top side of

Make sure the final operation is done with a hone so that

75 percent of more of bearing surface contacts the

expander spacer with gap of segment approximately 90

piston pin.

beyond gap of stainless steel expander spacer, making

(3) If the pistons and pins are not being

certain that the expander spacer ends are still in a

replaced, check the clearance between the piston pins

butted position.

(c) Install second segment on bottom

and the sleeve bearings. Clearance must be between

0.0002 and 0.0006 inch. If clearance is not within this

side of the expander spacer with segment gap

tolerance, press new sleeve bearings into the

approximately 90 from the expander gap in opposite

connecting rods and ream and hone to provide the

direction from which the top segment has been installed.

(d) Recheck assembly. Rings should

proper clearance. After honing, 75 percent of the sleeve

bearing surface must contact the piston pin.

be free to move in the groove; however, a slight drag

(4) When pins, bushings, and pistons of the

will be evident because of the side sealing action of the

proper size have been found, assemble the pistons to

ring assembly. Be sure expander spacer ends remain

the connecting rods as follows:

butted.

(a) Heat the pistons and connecting

(7) Install the remaining piston rings on the

rods in an oven or in water to a minimum of 160F.

piston with a standard ring expander tool.

(b) Position a connecting rod in its

(8) Assemble the remaining pistons,

piston. Install the piston pin; secure with the piston pin

connecting rods, and piston rings.

retaining ring (15, fig. 4-14).

(9) Install the assembled pistons and

(5) Slide the piston rings (17) squarely into

connecting rods in the same cylinders from which they

the cylinders in which they will be used. Check the ring

were originally removed. Use a ring compressor to

gap with feeler gage. If the ring gap is not at least 0.007

compress the piston rings. Lubricate the pistons and

inch, file the rings to provide a larger gap. If the ring

cylinder walls with engine oil before installing the

gap exceeds 0.017 inch, rebore the cylinders (para 4-13)

pistons. Wrap the bottom end of the connecting rods

and install oversize pistons and rings.

with a cloth to prevent damage to the cylinder walls

during installation.

4-21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |