|

|||

|

|

|||

|

Page Title:

CHAPTER 2. DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE |

|

||

| ||||||||||

|

|

TM 5-4320-258-34

CHAPTER 2

DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE

SECTION I. REPAIR PARTS, SPECIAL TOOLS, AND EQUIPMENT

2-1. Special Tools and Equipment

the repair parts and special tools list covering direct

support and general support maintenance for this

No special tools and equipment are required for the

centrifugal pump. Refer to TM 5-4320-258-35P (when

direct support and general support maintenance of the

printed).

centrifugal pump.

2-2. Maintenance Repair Parts

Repair parts and equipment are listed and illustrated in

SECTION II. TROUBLESHOOTING

2-3. General

the scope of operator/crew and organizational

maintenance, refer to TM 5-4320-258-12.

This section describes troubles which might occur during

2-4. Direct Support and General Support

operation of the centrifugal pump, along with the

Maintenance Troubleshooting

probable causes and corrective actions relating to the

troubles. Only those functions which are solely within

Refer to table 2-1 for troubleshooting which is allocated

the scope of direct and general support maintenance are

to direct support and general support maintenance

listed. For trouble shooting procedures which are within

levels.

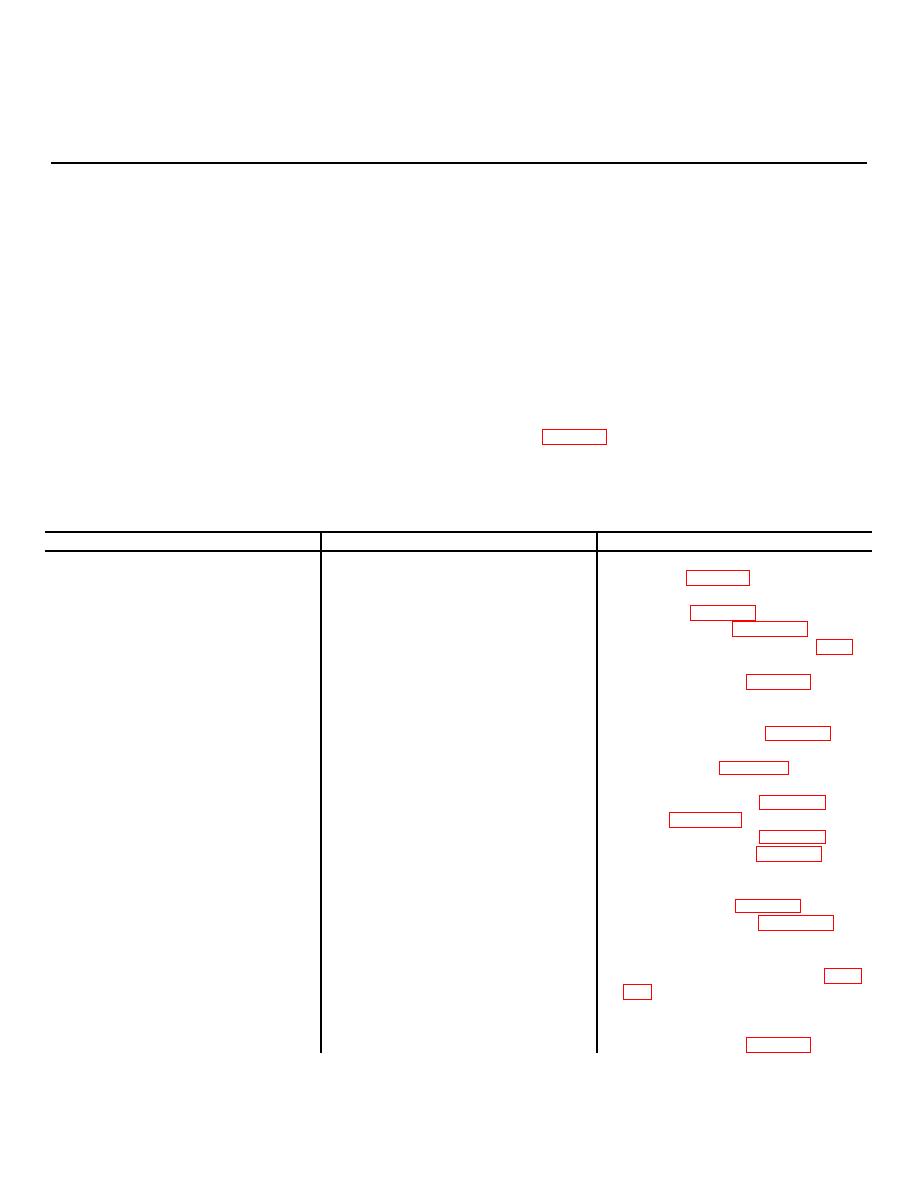

Table 2-1. Troubleshooting

Malfunction

Probable Cause

Corrective Action

1. Engine will not crank.

a. Impeller binding in volute.

a. Disassemble pump and free

impeller (para 5-4).

b. Impeller bearings binding in

b. Disassemble pump and replace

bearing housing.

Bearings (para 5-4).

c. Engine seized.

c. Remove engine (para 2-10).

Repair engine as necessary (para

4-3 through 4-13).

2. Engine cranks but will not start.

a. Carburetor defective.

a. Repair carburetor (para 3-3).

b. Engine compression too low.

b. Test engine to determine fault

(TM 5-4320-258-12). Repair

engine as necessary (para 4-3

through 4-13).

3. Water temperature safety switch

a. Radiator clogged, causing engine

a. Clean radiator (para 3-7).

Stops engine operation.

Overheating.

b. Cylinder head or block badly

b. Clean cylinder head (Para 4-3) or

scaled.

Block (para 4-13).

c. Safety switch improperly adjusted.

c. Adjust safety switch (para 3-9).

d. Water pump defective.

d. Repair water pump (para 3-8).

4. Oil pressure safety switch stops

a. Oil pressure regulator valve im-

a. Adjust regulator valve (para 3-

engine operation.

Properly adjusted.

13).

b. Oil pump defective.

b. Repair oil pump (para 4-7).

c. Safety switch improperly adjusted.

c. Adjust safety switch (para 3-12).

5. Engine overspeed governor trips.

a. Overspeed governor not properly

a. Adjusted overspeed governor (para

adjusted.

3-5).

b. Overspeed governor defective.

b. Replace overspeed governor (para

6. Engine lacks power, smokes, or

a. Carburetor float level incorrect.

a. Adjust carburetor float level (para

operates erratically.

3-3).

b. Carburetor defective.

b. Repair carburetor (para 3-3).

2-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |