|

|||

|

|

|||

|

Page Title:

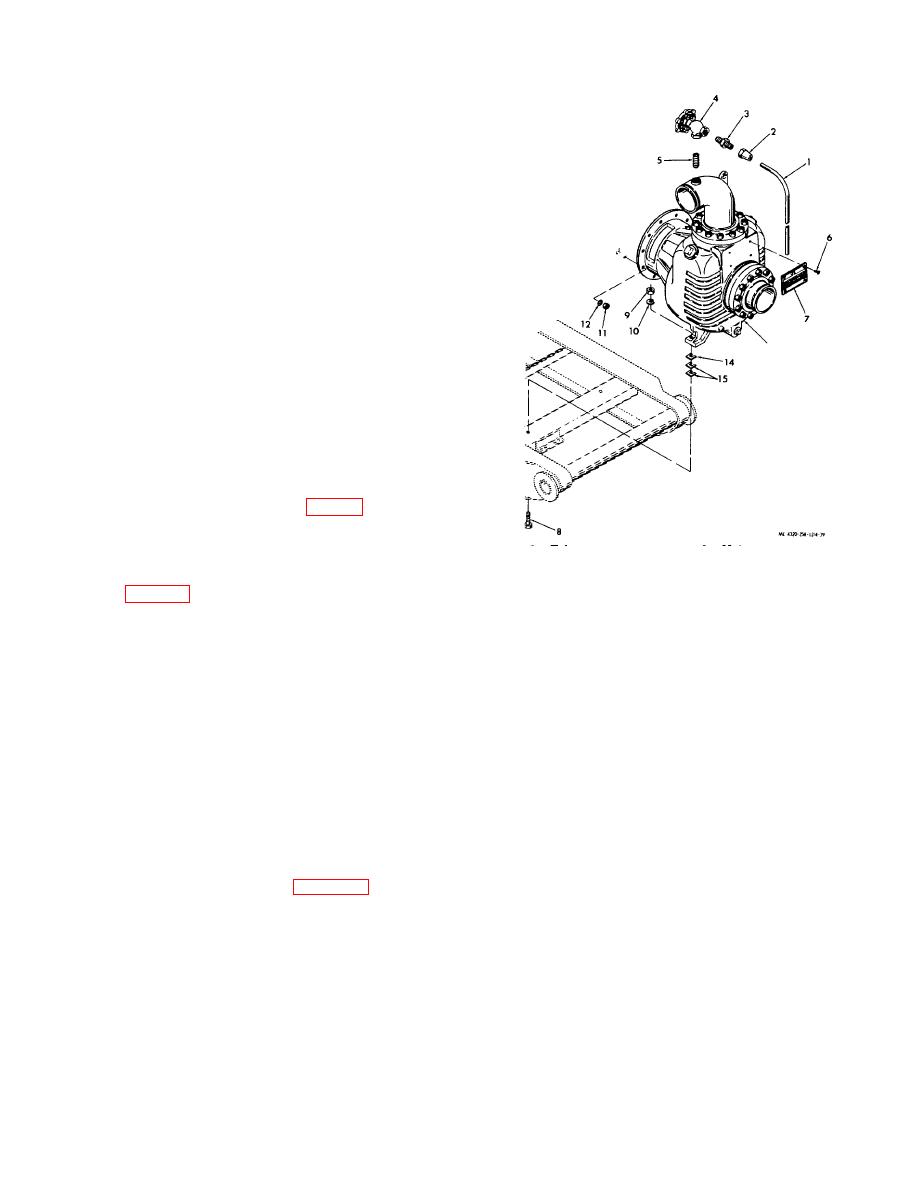

Section XIV. MAINTENANCE OF PUMP AND |

|

||

| ||||||||||

|

|

Section XIV. MAINTENANCE OF PUMP AND

COUPLING

4-46. Description

a. The pump is secured to the flywheel housing of

the engine and to the skid which mounts both the engine

and pump. The pump shaft is secured to the engine

flywheel through a flexible coupling, one member of

which is keyed to the pump shaft and the other half of

which is bolted to a drive plate that is bolted to the

flywheel.

b. Pump alignment is attained by the installation of

horseshoe-type shims which are placed between the

mounting feet of the pump body and the skid. Adding or

removing shims raises or lowers the pump as required

to aline it with the engine flywheel and flywheel housing.

The engine and pump must be closely alined to assure a

smooth transfer of power from the engine to the pump,

even though the flexible coupling will tolerate a small

amount of misalignment of the drive system.

4-47. Centrifugal Pump

a. Removal.

(1) Remove the drain plug (fig. 1-1) from the

centrifugal pump.

(2) Disconnect all suction and discharge

piping from the pump.

(3) Remove the air eliminator valve (items 1

1.

Tube

9.

Nut

through 5, fig. 4-39).

2.

Tube nut

10.

Lock washer

(4) Support the weight of the pump with a

3.

Connector

11.

Nut

hoist or crane hooked into the lifting eye welded onto the

4.

Air eliminator valve

12.

Lock washer

discharge elbow.

6.

Pipe nipple

13.

Centrifugal pump

(5) Remove the nuts (11) and lock washers

6.

Screw

14.

Shim

(12) that secure the bearing housing of the pump (13) to

7.

Identification plate

15.

Shim

the flywheel housing of the engine.

8.

Cap screw

16.

Stud

(6) Remove the cap screws (8), nuts (9), and

lock washers (10) that secure the pump to the skid.

Figure 4-39.

Centrifugal pump, removal and

Operate the hoist or crane so that the pump feet just

installation.

clear the skid. Pull straight out on the pump to

disengage the pump half of the flexible coupling from

(3) Inspect the pump for a cracked or dented

the engine half of the coupling. Take care to prevent

housing, suction flange, or discharge elbow. Attempt to

losing the cushions that are installed between the

turn the pump shaft. It must turn freely and smoothly,

coupling halves. Remove the pump and shims (14 and

without catching or binding. Reach into the pump

15).

through the suction flange and check the operation of

the check valve. It must operate freely and must make

(7) Remove the coupling (para 4-48a).

a good seal against its seat.

Report any pump

deficiencies to direct support maintenance.

b. Cleaning and Inspection.

(4) Inspect the air eliminator valve for rough

or catching operation and for cracked or damaged

(1) Clean the exterior of the pump with a

threads. Replace a damaged valve.

cloth dampened with cleaning solvent (fed. spec.P-D-

(5) Inspect all other parts for cracks,

680); dry thoroughly.

distortion, and other damage; replace damaged parts.

(2) Wash the air eliminator valve and related

parts with cleaning solvent (fed. spec. PD-680) ; dry

thoroughly.

4-43

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |