|

|||

|

|

|||

|

Page Title:

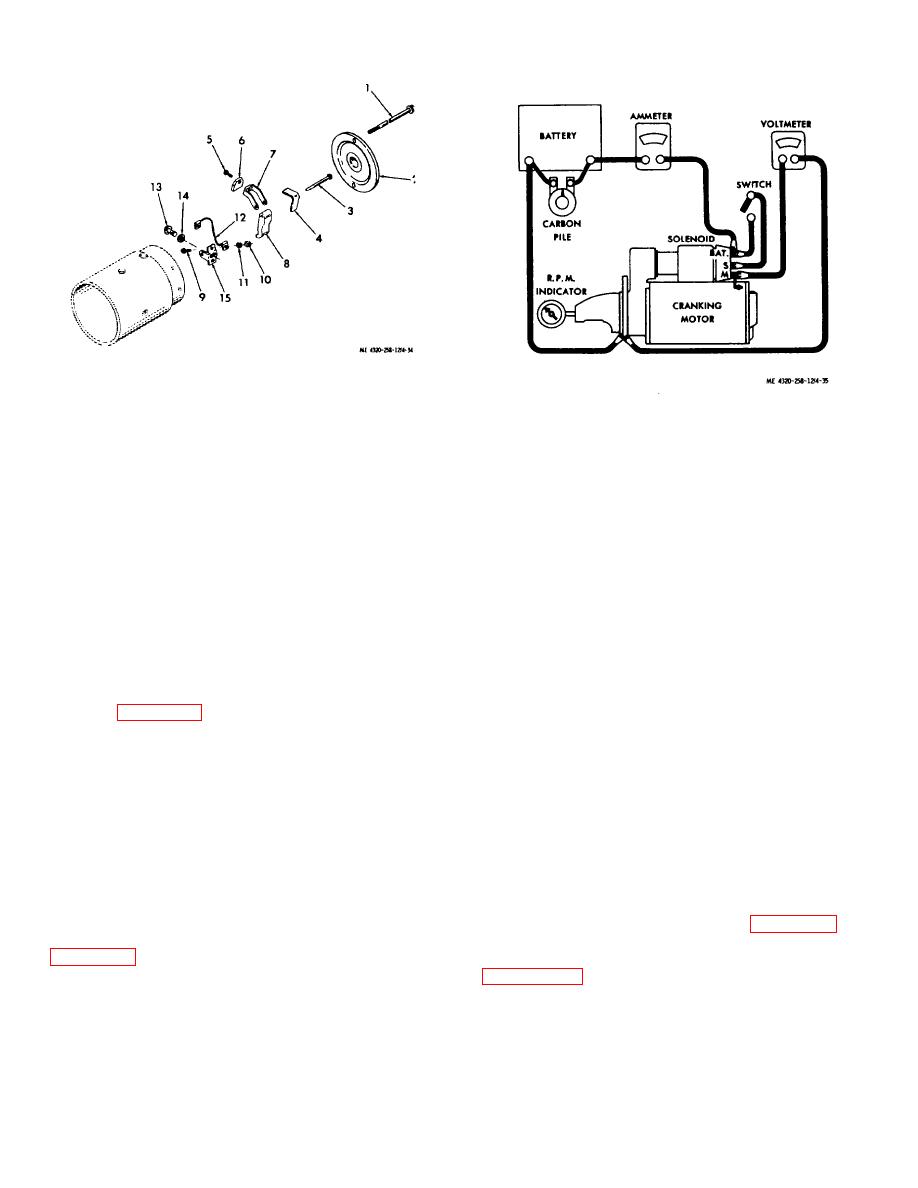

Figure 4-34. Engine starter brushes, exploded view. |

|

||

| ||||||||||

|

|

1. Thru bolt

8.

Insulated brush

2. Commutator end

holder

frame

9.

Brush lead screw

Figure 4-35. Engine starter test setup.

3. Support pin

10.

Nut

4. Brush spring

11.

Lock washer

open and the carbon pile rheostat at a non-load

5. Brush screw

12.

Grounded brush lead

condition. Just prior to closing the switch, operate the

6. Brush

13.

Brush support screw

carbon pile rheostat to load the battery.

7. Grounded brush

14.

Washer

holder

15.

Brush support

(3) Close the switch and adjust the carbon

pile rheostat to provide a 20-volt indication on the

Figure 4-34. Engine starter brushes, exploded view.

voltmeter. The starter must operate at a high rate of

speed. Allow the starter to gain full speed rotation and

(3) Remove the screws (13) and washers (14)

check the indication of the tachometer. It must read

that secure the brush leads (12) to the brush support

3300 and 5600 rpm.

(15); remove the brush leads.

(4) With the starter operating in the required

(4) Replace brushes if they are chipped, oil

speed range, check the indication on the ammeter.

soaked, or worn to less than 5/16 inch. Replace any

Current draw shall not exceed 40 to 75 amperes. This

other parts that are cracked, worn, or distorted.

includes the draw of the solenoid.

(5) Install the brushes and related parts as

(5) Open the switch and disconnect the

shown in figure 4-34. Before. installing the commutator

starter. Disconnect the carbon pile rheostat to prevent it

end frame (2), seat the brushes on the commutator,

from draining the battery.

using 00 sandpaper.

(6) If the starter fails to operate within the

required range of speeds and amperages at 20 volts,

Note. The commutator on the armature shaft

replace the starter.

must be smooth and concentric, free from burrs,

scoring, high segments, or other damage. Replace the

e. Installation.

engine starter if the commutator is damaged (6) Install

the commutator end frame (2) with the thru bolts (1).

(1) Position the engine starter (7, fig. 426)

with its assembled solenoid switch (6) on the flywheel

d. Starter Bench Testing. Check the operation of

housing of the engine; secure with three cap screws and

the starter on a bench as follows:

lock washers.

(2) If necessary, refer to figure 1-3 for

(1) Set up the starter for testing as shown in

connection information.

(3) Attempt to start the engine as directed in

prior to the test.

and

easily.

Caution: Take care not to exceed a 20-volt

input to the starter during this test. Higher voltages

may cause the starter to throw its windings.

(2) Make all test setups with the switch

4-38

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |