|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

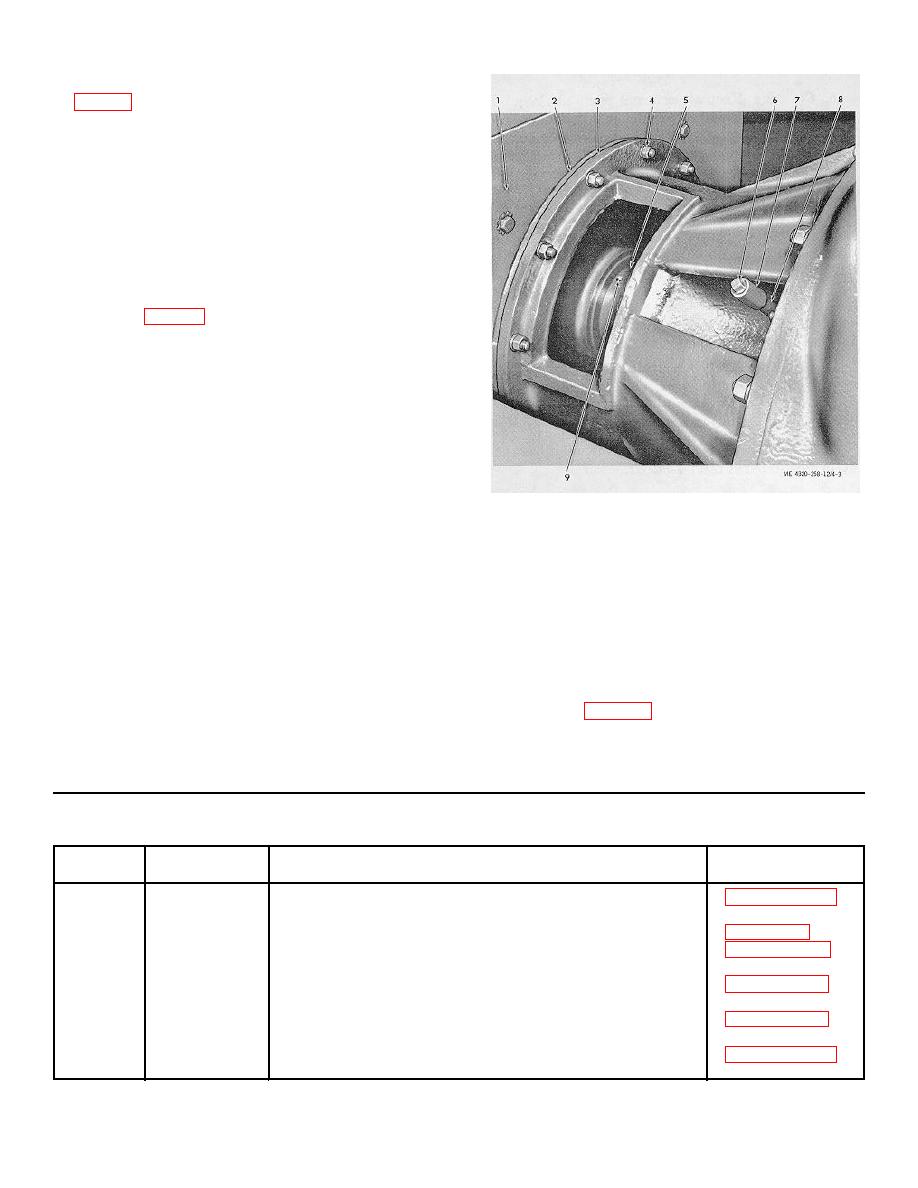

(3, fig. 4-2) have a lubrication fitting (1) which must be

serviced every 1000 operating hours. Use a hand

grease gun and apply grease until overflow appears

through the port holes of the fitting. Use automotive

grease for this purpose.

4-10. Pump Lubrication

grease by the manufacturer at assembly and require no

subsequent lubrication except at overhaul periods. No

other pump lubrication is required, except for seal

lubrication prior to storage.

b. Prior to storage of 30 days or more, remove the

pipe plug (6, fig. 4-3) from the pipe coupling (7) and

pour 1/2 pint of preservative oil into the seal lubricant

pipe (8) to oil the seal. Install the pipe plug.

1.

Engine housing

5. Pump coupling

2.

Flywheel housing

6. Plug

3.

Pump bearing housing 7. Pipe coupling

4.

Pump-to-engine

8. Seal lubricant pipe

mounting nut

9. Coupling setscrew hole

Figure 4-3. Engine-to-pump connections.

Section V. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

maintenance and includes additional services which are

4-11. General

allocated to organizational maintenance.

This section lists the preventive maintenance checks

4-12. Preventive Maintenance Checks and Services

and services which shall be performed on a monthly or

quarterly basis by organizational maintenance

Refer to table 4-1 for a listing of the preventive

personnel. It includes and expands upon the preventive

maintenance checks and services which are allocated to

maintenance services performed daily by operator/crew

organizational maintenance.

Table 4-1. Preventive Maintenance Checks and Services

Monthly Schedule

Organizational Maintenance Category

(or Quarterly)

Sequence

Item to be

Paragraph

number

inspected

Procedures

reference

1

Fuel tank

Drain tank if fuel is dirty or contaminated. Refill with proper

grade of gasoline.

2

Pump mounting

Tighten loose hardware. Replace missing hardware.

3

Batteries

Check battery condition with hydrometer. Replace batteries if

they fail to take and maintain a charge.

4

Radiator

Fill to required level with proper antifreeze solution. Replace

radiator if damaged or leaking.

or 4-31.

5

Engine oil

Change engine oil at required interval. Service filter if neces-

sary.

6

Fan drive belt

Belt must deflect to 1 inch with thumb pressure at midpoint

of longest belt span. Adjust if loose. Replace defective belt.

4-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |