|

|||

|

|

|||

|

Page Title:

Engine Lubrication |

|

||

| ||||||||||

|

|

oil into the engine. Use the engine oil required for the

b. Cleaning. Keep all external parts not requiring

particular temperature range which will be encountered.

lubrication clean of lubricants. Before lubricating the

Required grades of engine oils are as follows:

equipment, wipe all lubrication points free of dirt and

Below 0

F 0-32

F

32-75

F

Above 75

F

grease. Clean all lubrication points after lubricating to

5W-20

10w

SAE20W

SAE30

prevent accumulation of foreign matter.

(6) Check the oil level on the oil level dipstick

c. Points of Lubrication. Service the lubrication

(8, fig. 4-26). It must be up to the full mark. Add oil if

points at proper intervals as illustrated in the current

necessary, but do not overfill.

Lubrication Order: Refer to DA Pam, 310-4 for the

current Lubrication Order.

d. OES Oil.

adapter and its mating gear teeth on the overspeed

(1) The crankcase oil level must be checked

governor drive shaft. Weekly, turn the grease cup

frequently, as oil consumption may increase.

clockwise two full turns to provide grease to the gear

(2) The oil may require changing more

teeth. When the grease cup is turned down all the way,

frequently than usual because contamination by fuel

refill it with automotive grease and reinstall it.

dilution and sludge formation will increase under cold

weather operation conditions.

e. Oil Filter Service. Service the oil filter as

described in paragraph 4-9a(3).

4-9. Engine Lubrication

of changing the oil in the crankcase and servicing the oil

filter. Change oil every 50 operating hours and change

the oil filter every 150 operating hours. Proceed as

follows:

(1) Run the engine long enough to heat it to

operating temperature. This is important since warm oil

will drain from the internal engine parts much more

rapidly than cold oil. The warm oil will carry more dirt

and sludge with it as it drains.

(2) Place suitable containers under the

engine drain ports and remove the oil pan drain plug (4,

drain fully.

(3) Every third oil change (150 operating

hours maximum), service the engine oil filter as follows:

(a) Use a wrench on the hex head of

the screw on the top of the oil filter (3, fig. 4-26) and

remove the filter cover and gasket.

(b) Grasp the filter element by its

handle and lift it from the filter housing. Discard the

filter element.

(c) Wipe the interior of the filter

housing with a clean, dry cloth.

(d) Position a new filter element in the

filter housing.

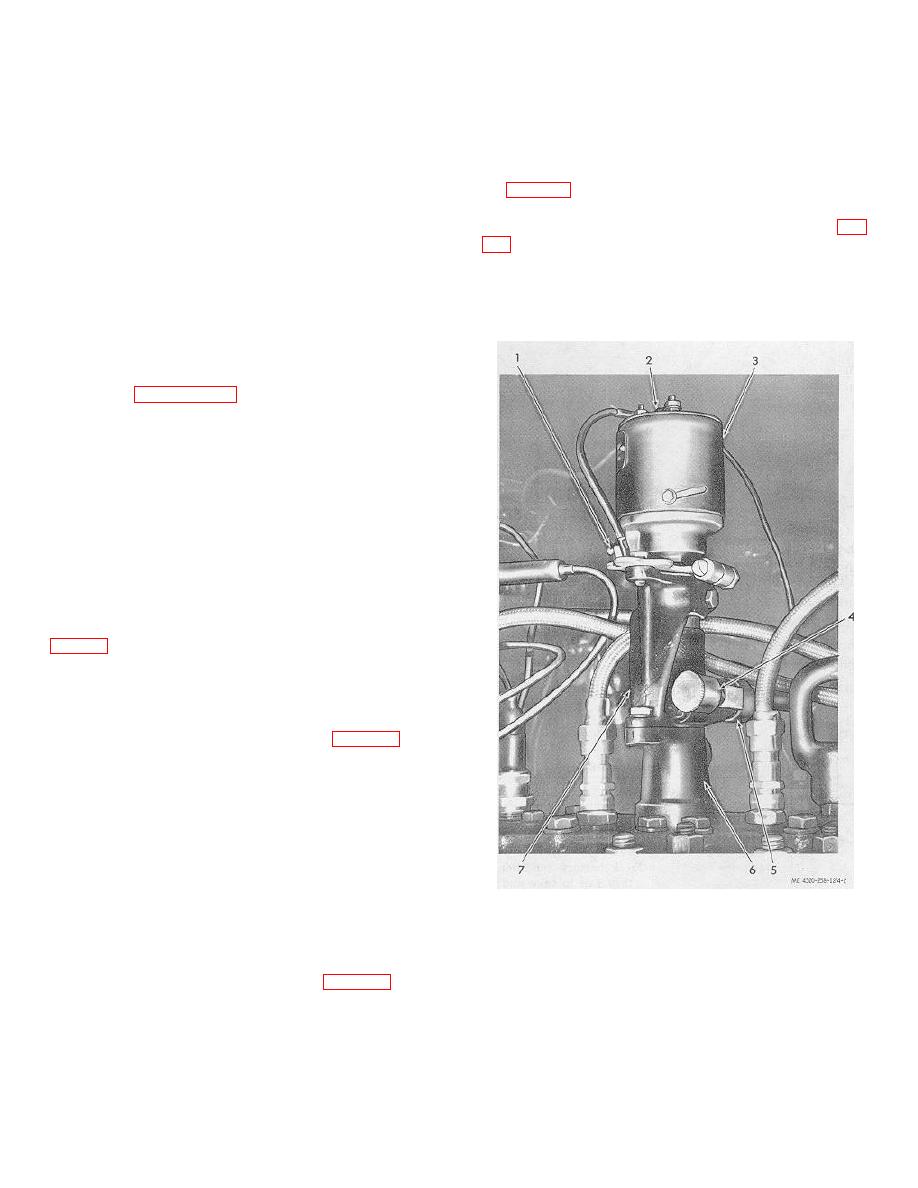

1.

Lubrication fitting

5. Tachometer shaft

(e) Install the cover and gasket on the

2.

Reset button

connection

filter and tighten the hex screw at the top of the filter to

3.

Overspeed governor

6. Drive adapter

secure the cover.

4.

Tachometer drive

7. Governor arm

(4) Install the plugs in the drain ports.

grease cup

(5) Remove the filler cap (11, fig. 4-26) from

Figure 4-2. Tachometer drive and engine overspeed

the engine oil filler pipe and pour 5 1/2 quarts of engine

governor, showing lubrication points.

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |