|

|||

|

|

|||

|

Page Title:

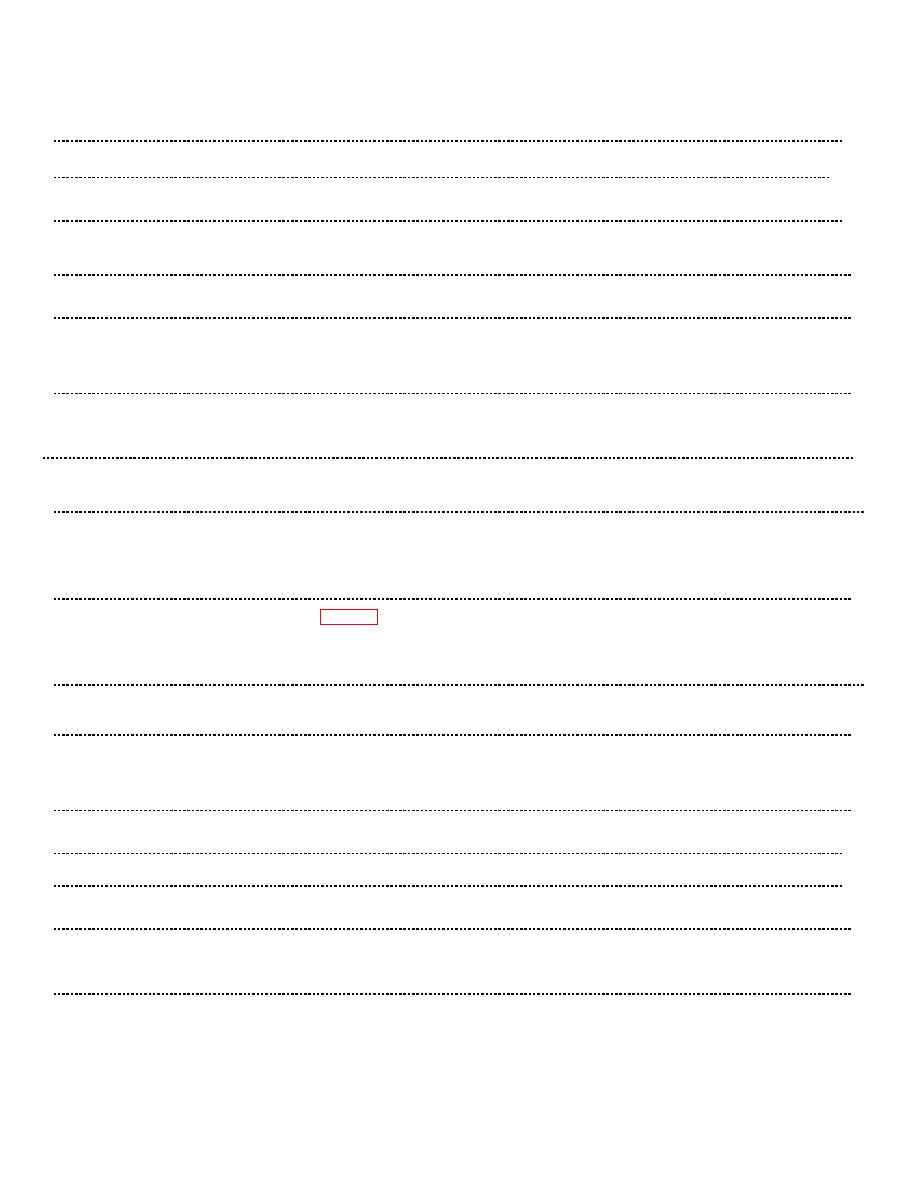

FIGURE 3-1. PREVENTIVE MAINTENANCE SERVICES |

|

||

| ||||||||||

|

|

FIGURE 3-1. PREVENTIVE MAINTENANCE SERVICES

ITEM

PARA.

REF.

DAILY MAINTENANCE SERVICES

1.

ENGINE - Refer to 9M 5-2805-259-14 for daily maintenance services.

2.

MUFFLER - Check for cracks, holes, rust, leaking gaskets, and insecure mounting.

3-14

3

TIRES - Check and adjust inflation to 25-30 PSI. Inspect for cuts, breaks, blisters, and

flat spots. Inspect valve stems for leaks. Replace missing valve caps.

3-16. D

4.

FUEL TANK - Check fuel level. Inspect for leaks. Inspect strainer

for damage.

3-15

5.

HOSE CONNECTIONS AND SEALING PLUGS - Inspect hoses for secure con-

nection. Inspect for leaks in suction line. When hoses are discon-

nected, make sure that sealing plugs are installed.

2-7

6.

CONTROLS AND INSTRUMENTS - Inspect for damage and insecure mounting.

Inspect for defective wiring and loose or leaking connections. With

2-9

&

unit operating, inspect for proper operation of gages and switches.

3-13.

A

7.

FUEL STRAINER (SEDIMENT BOWL) - Inspect for loose mounting, leaks,

and cracks in bowl. Drain water & dirt from the bowl (Weekly).3-15

8.

BATTERY - Tighten loose cables and mounting. Remove corrosion.

Fill to 3/8 inch above battery plates. In freezing weather, run

engine a minimum of one hour after adding water. Clean vent holes

in filler caps (Weekly).

3-13. C

9.

Remove drain plug (item 33, fig. 4-1) from intermediate housing and flash

entire pump with fresh water. A daily increase in amount of drainage from

intermediate housing indicates a defective seal (AOO4-M36) and seal must

be replaced.

QUARTERIY PREVENTIVE PAINTENANCE SERVICES

10.

ENGINE - Refer to TIM 5-2805-259-14 for quarterly maintenance services.

11.

WHEELS - Inspect for loose or missing lug nuts and for leaking grease

seals. Check wheel bearings for proper adjustment. Inspect rims for

3-16.

D&

damage.

3-16.

E

12.

TRAILER FRAME AND MOUNTING HARDWARE - Inspect for damage. Tighten

all loose components and mounting hardware.

3-16

13.

REFLECTORS - Inspect for broken lenses and insecure mounting.

3-16.

B

14.

DRAWBAR - Inspect for broken welds and lost or damaged parts.

3-16.

B

15.

PUMP - Thoroughly flush casing with clean water. Inspect for damage

or leaks. Drain intermediate housing. If it fills with water fre-

quently, the seal is defective and must be replaced.

3-4

13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |