|

|||

|

|

|||

|

Page Title:

Section V. MAINTENANCE OF FUEL SYSTEM |

|

||

| ||||||||||

|

|

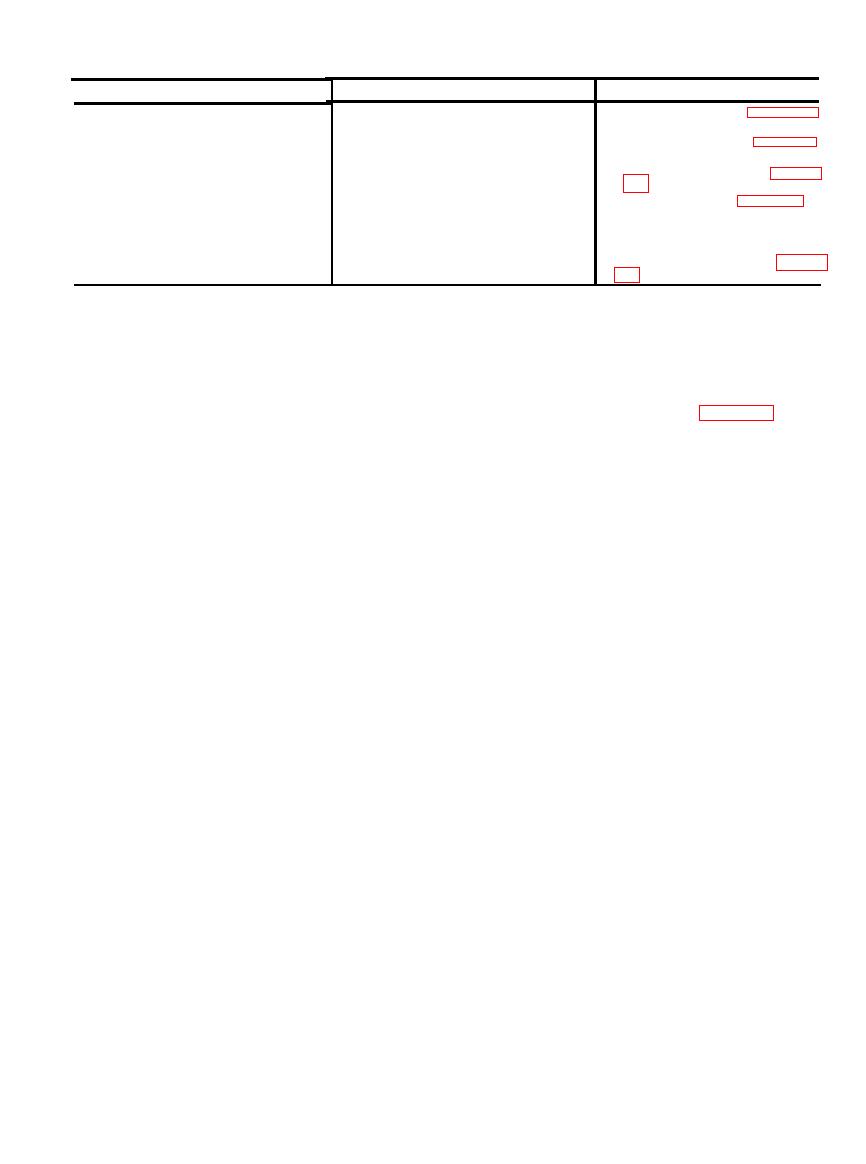

Table 4-2. Organizational Maintenance Troubleshooting Chart--Continued

Corrective action

Probable

cause

Malfunction

b. Slight leak in diaphragm.

b. R e p l a c e d i a p h r a g m ( p a r a 4 - 1 8

through 4-20 ).

c. Cracked diaphragm pot.

through 4-20 ).

a. Plunger bearing defective.

4. Pump is noisy

b. Plunger spring length too long,

allowing plunger to strike pot.

c. Debris caught in diaphragm pot.

c. Clean pot of debris.

a. Replace wheel.

a. Wheel

defective.

5. Wheels fail to turn or turn with

b. Axle bent.

difficulty.

Section V. MAINTENANCE OF FUEL SYSTEM

4 - 1 0 . Disassembly

4-9. Description

Disassemble the fuel tank, lines, fittings, and fuel

The fuel system consists of the fuel tank, fuel

strainer with shutoff valve, and the fuel lines and

t h e fuel tank prior to removing it from the

fittings. The fuel tank is mounted with straps which

secure it to brackets that are bolted to the pump

e q u i p m e n t . Unless chain or cap is damaged

val of permanently secured cap is unnecessary.

assembly.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |