|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

5.2.2.7.8

Assembly Rings to Piston.

Note the various rings and the proper position of each, especially the center

compression ring. The scraper groove should always be down toward the

piston skirt. Be sure the oil return holes are clean and carbon is removed

from all grooves. Install expander under oil ring in sleeve bore aluminum

alloy engines.

Oil the rings and piston skirt, then compress rings with ring compressor.

On all aluminum engines, use compressor.

Turn the piston and compressor upside down on the bench and push down-

ward, so the piston head and edge of compressor band are even while

tightening the compressor. Draw the compressor up tight to fully compress

the rings, then loosen the compressor very slightly.

NOTE: DO NOT ATTEMPT TO INSTALL PISTON AND RING ASSEMBLY

WITHOUT RING COMPRESSOR.

5.2.2.7.9

Install Piston and Rod Assembly.

Place the connecting rod and piston assembly with rings compressed into

the cylinder bore. Push piston and rod down into the cylinder. Oil the

crankpin of the crankshaft. Pull the connecting rod against the crankpin

and assemble the rod cap so assembly marks align.

NOTE: SOME RODS DO NOT HAVE ASSEMBLY MARKS AS ROD AND CAP

WILL FIT ONLY IN ONE POSITION.

Assemble the cap screws and screw locks with oil dipper (if used). Tighten

cap screws to torque shown in Table No. 9. Rotate the crankshaft two revo-

lutions to be sure rod is correctly installed. If rod strikes, connecting rod

has been installed wrong or cam gear is out of time. If crankshaft operates

freely, bend screw locks against screw heads.

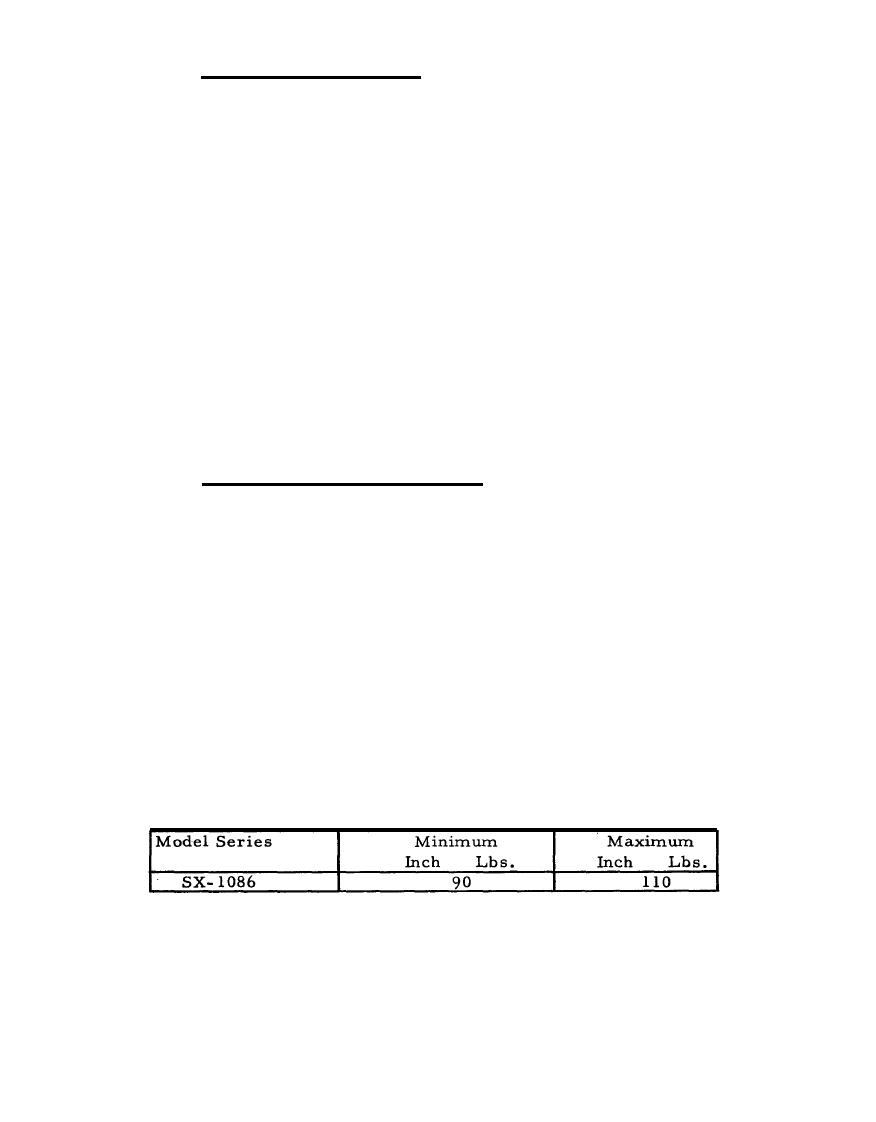

TABLE 9

CONNECTING ROD CAP SCREW TORQUE

N O T E : TIGHTEN ROD SCREWS SECURELY. AFTER TIGHTENING ROD

SCREWS, ROD SHOULD BE ABLE TO MOVE SIDEWAYS ON CRANKPIN OF

SHAFT . IF NOT, ADJUST. A TORQUE WRENCH SHOULD BE USED TO

65

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |