|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

If using a portable drill, cut a wood block to place inside of cylinder as a

stop for hone. Disconnect drive shaft from hone and raise it out of way.

5.2.2.6.4

To Hone Cylinder.

Place hone in middle of cylinder bore. Tighten adjusting knob with finger

or small screw driver until stones fit snugly against cylinder wall. DO

NOT FORCE. Hone should operate at 300 to 700 RPM.

Connect drive shaft to hone. Be sure that cylinder and hone are centered

and aligned with drive shaft and drill spindle. Start drill and, as hone

spins, move it up and down at lower end of cylinder. The cylinder is not

worn at the bottom but is round so it will guide the hone to straighten

cylinder bore. As the bottom of the cylinder increases diameter gradually

increase strokes until hone travels full length of bore, but do not extend

hone more than 3/4" to 1" at either end of cylinder bore.

As cutting tension decreases, stop hone and tighten adjusting knob. Check

cylinder bore frequently with an accurate micrometer. Hone about .0005"

large to allow for shrinkage when cylinder cools.

Change from rough stone to finishing stone when within .0015" of desired

size, then use finishing stones. Always bore .010", .020". or .030" above

the standard dimensions given in Table No. 1.

5.2.2.6.5

Cylinder Finish and Cleaning.

The finish resized cylinder should have a crosshatch appearance. Proper

stones, lubrication and spindle speed, along with rapid movement of hone

within the cylinder. during the last few strokes will produce this finish.

Crosshatching will allow proper lubrication and ring break-in.

It is most important that the cylinder be thoroughly cleaned after honing to

eliminate all grit. Wash the cylinder carefully in a solvent such as kerosene.

The cylinder bore should be cleaned with a brush, soap, and water.

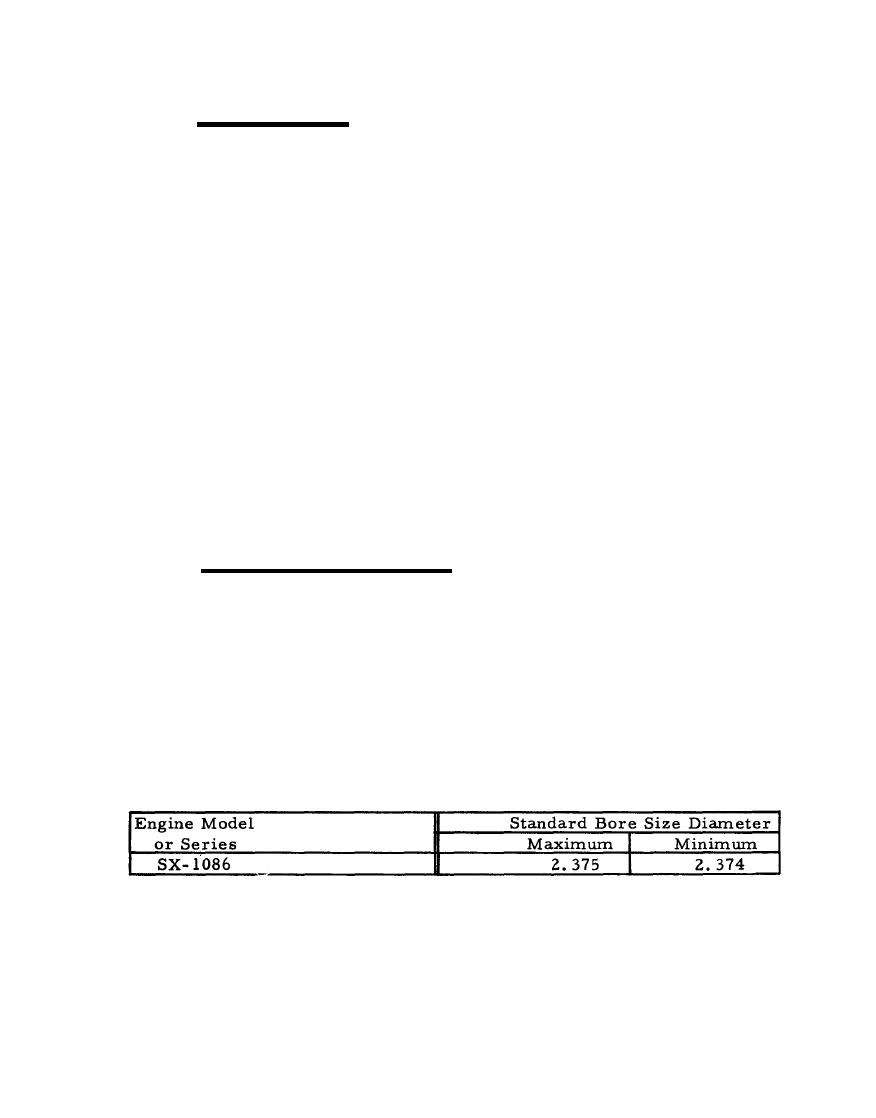

TABLE 5

BORE DIMENSIONS

62

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |