|

|||

|

|

|||

|

Page Title:

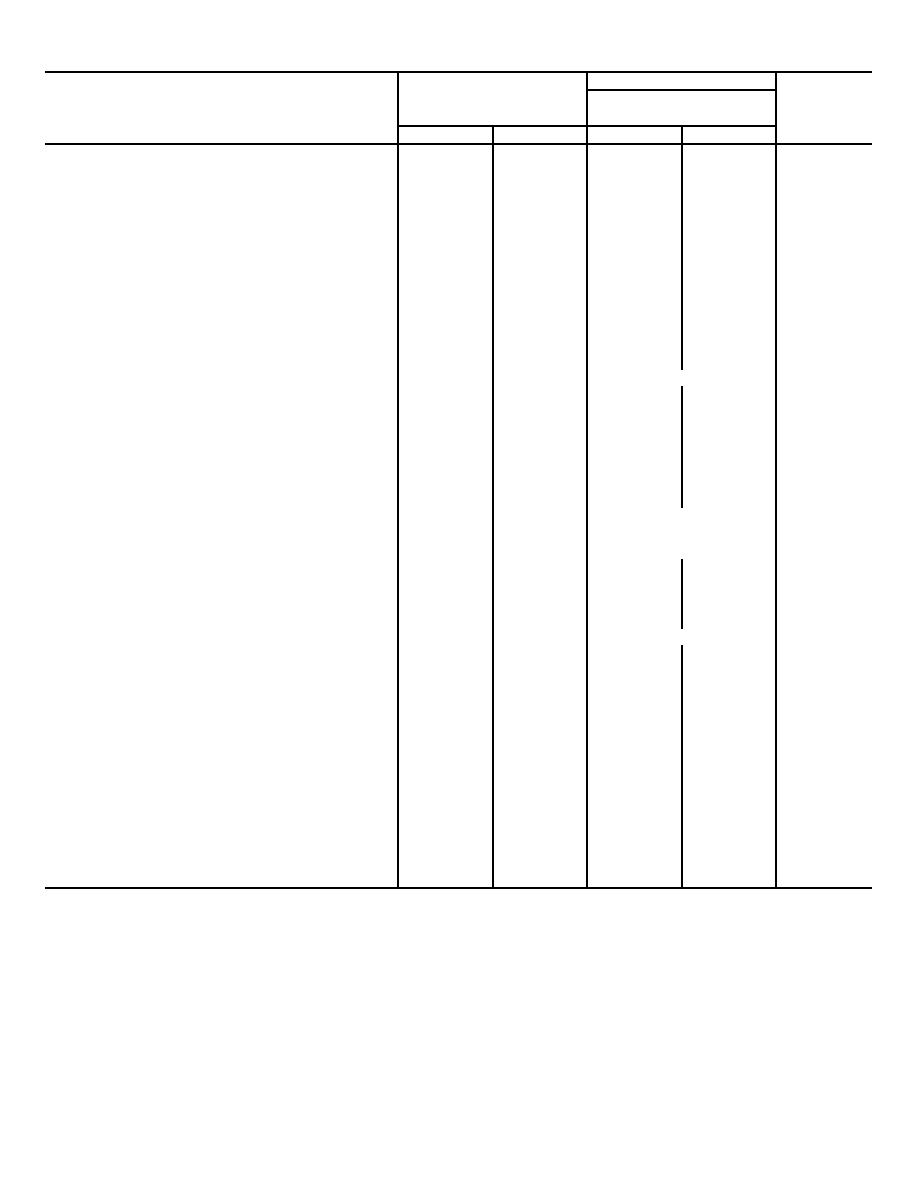

Table 4-1. Engine Repair and Replacement Standards-continued |

|

||

| ||||||||||

|

|

Table 4-1. Engine Repair and Replacement Standards-Continued.

Manufacturer's

Maximum

dimensions and

allowable

tolerances in inches

Desired clearance

wear and

Maximum

Minimum

Maximum

Minimum

clearance

Ring groove width:

Top groove ................................ ....................

0.097

0.098

-----

-----

0.100

Second and third ................................ ............

0.1265

0.1275

-----

-----

0.1295

Fourth groove ................................ ................

0.2510

0.2520

-----

-----

0.2540

Piston fit in cylinder bore on high side of piston:

Clearance ................................ ......................

-----

-----

-----

0.006

Pounds pull................................ .....................

5 lb

10 lb

Pinhole diameter ................................ ...............

1.4995

1.4998

PISTON PINS

Piston pin length ................................ ................

4.433

4.438

Piston pin diameter ................................ ...........

1.4994

1.4996

-----

-----

1.4991

Pin-to-bushing clearance ................................ ...

-----

-----

0.0003

0.0008

(0 0005 desired)

CONNECTING RODS

Bushing hole diameter ................................ ......

1.6870

1.6880

Finished inside diameter of bushing ..................

1.4999

1.5002

-----

-----

1.5012

Bearing hole diameter ................................ .......

3.1505

3.1510

CONNECTING ROD BEARINGS

Thickness ................................ ..........................

0.0748

0.0753

-----

-----

0.0743

Bearing-to-journal clearance ..............................

-----

-----

0 002

0 004

0 0055

(0 003 desired)

Side play................................ ............................

----

-----

0 005

0 010

(0 006 desired)

MAIN BEARINGS

Thickness................................ ...........................

0.1248

0.1253

-----

-----

0.1243

Diameter ................................ ...........................

3.2514

3.2534

Bearing-to-journal clearance ..............................

-----

-----

0.0014

0.0044

(0.003 desired)

CRANKSHAFT

Main bearing journal diameter............................

3.249

3.250

-----

-----

3.247

Connecting rod bearing journal diameter ...........

2.9974

2.9983

2.9964

End play................................ .............................

-----

-----

0.006

0.010

CYLINDER ASSEMBLY

Cylinder bore diameter................................ .......

5.0000

5.0005

Cylinder stroke ................................ ..................

5.375

Cylinder out-of-round:

Top ................................ ................................

-----

-----

-----

-----

0.001

Bottom ................................ ...........................

-----

-----

-----

-----

0.005

Cylinder taper:

Top ................................ ................................

-----

-----

-----

-----

0.001

Bottom ................................ ............................

0.010

Main bearing bore diameter ..............................

3.5020

3.5030

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |