|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

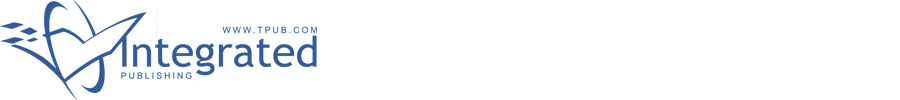

Table 3-2. Operator/ Crew

Preventive Maintenance Checks and Services

D-Daily

W-Weekly

Time required 1.1

Time required .3 hrs.

Interval

Item to be inspected

Work

and

procedure

time

sequence No.

M/H

D

W

1

AIR SHROUD

.1

Inspect air shrouds for insecure mounting, trends, or cracks. Inspect

flywheel vanes for cracks or breaks.

2.

FUEL STRAINER

.1

Inspect for loose mounting, leaks, and cracked bowl. Drain water and

dirt from strainer.

3.

BATTERY

.1

Tighten loose cables and mountings.

Remove corrosion.

Fill

electrolyte to 3/8 in. above plates. In freezing weather run engine a

minimum of one hour after adding water. Clean vent hole in filler cap.

Section III. TROUBLESHOOTING

do not correct the malfunction, report the trouble to

3-5. General

organizational maintenance.

This section describes malfunction which might occur

3-6. Operator / Crew Troubleshooting

during operation of the pump assembly along with the

See table 3-3 for troubleshooting the pump unit.

test or inspection given and the corrective action taken.

Refer to TM 5-2805-259-14 for engine troubleshooting

Only those malfunctions which are within the

instructions.

maintenance scope of the operator / crew are included

in this chart. If the corrective actions given in this chart

Table 3-3. Troubleshooting

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1

PUMP ASSEMB3LY FAILS TO PRIME

Step 1. Check to see if pump has been primed.

Prime pump, refer to figure 2-2 (1).

Step 2. Check to see if suction lift is too high.

Place the pump assembly closer to level of supply if possible.

Step 3. Check to see if engine is running at rated speed.

Increase engine speed.

2.

PUMP FAILS TO DELIVER CAPACITY

Step 1. Check to see if suction lift is too high.

Place the pump assembly closer to level of supply if possible.

Step 2. Check to see if discharge head is too high.

Reduce total head.

Step 3. Check to see if engine is running at rated speed.

Increase engine speed.

Step 4. Check to see if suction or discharge valve is partially closed.

Adjust valves (fig. 2-1).

3.

NOISY PUMP OPERATION

Check for proper installation.

Relocate pump assembly.

4.

PUMP OVERHEATS

Check to see if suction or discharge valves are closed.

Open valves (fig. 2-2).

5.

NOT ENOUGH PRESSURE

Step 1. Check to see if engine is running at rated speed.

Increase engine speed (fig. 2-1).

Step 2. Check to see if valves are fully opened.

Open valves (fig. 2-2).

Note.

Suction and Discharge hoses, valves, fittings and connections must be free of leaks to attain rated capacities

3-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |