|

|||

|

|

|||

|

Page Title:

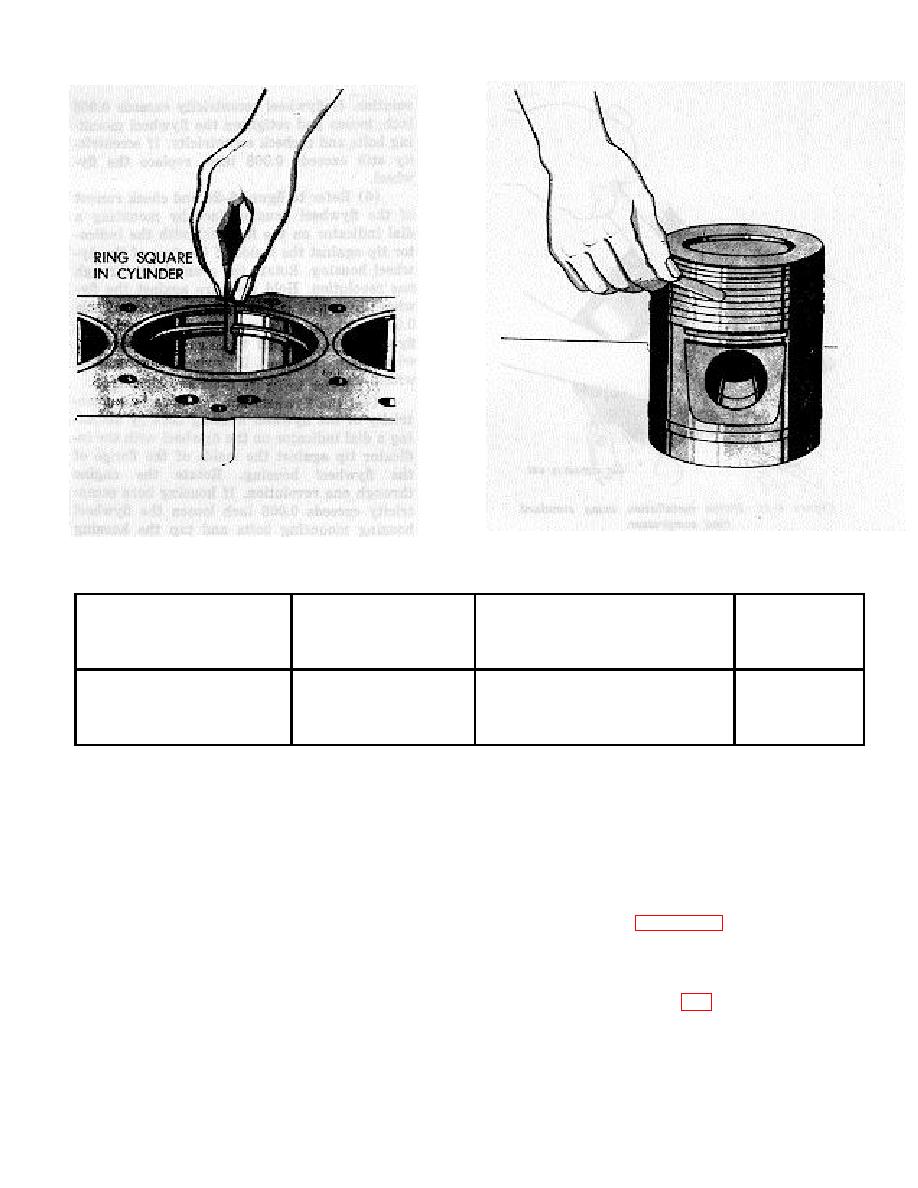

Figure 6-21. Checking piston ring clearance. |

|

||

| ||||||||||

|

|

CHECK RING GAP

PISTON RING SIDE CLEARANCE

MAX. WEAR

MAX. WEAR

RING GAP

BEFORE

GROOVE CLEARANCE

BEFORE

REPLACING

REPLACING

TOP

.010"-.020"

.045"

TOP

.022 "-.004 "

.006"

2ND

.010"-.020"

.045"

2ND

.0015"-.0035"

.006"

3RD & 4TH

.010"-.020"

.045"

3RD & 4TH .0005"-.0035"

.006"

MEC 4320-240-15,' 6-21

Figure 6-21. Checking piston ring clearance.

screws (8) and washers (7) remove housing (1).

(4) Replace damaged or defective parts.

c. Cleaning, inspection, and repair.

d. Installation.

(1) Clean all parts in an approved cleaning

(1) Refer to figure 6-24 and install flywheel

solvent. Dry with clean, dry, compressed air.

housing.

(2) Inspect the flywheel housing for / cracks,

(2) If the teeth on the flywheel ring gear are

damaged sealing surfaces, or other defects.

damaged, replace the ring gear as follows: Cut the ring

(3) Inspect the flywheel for damaged teeth,

gear with a torch or hacksaw and

cracks, distortion, or other defects.

6-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |