|

|||

|

|

|||

|

Page Title:

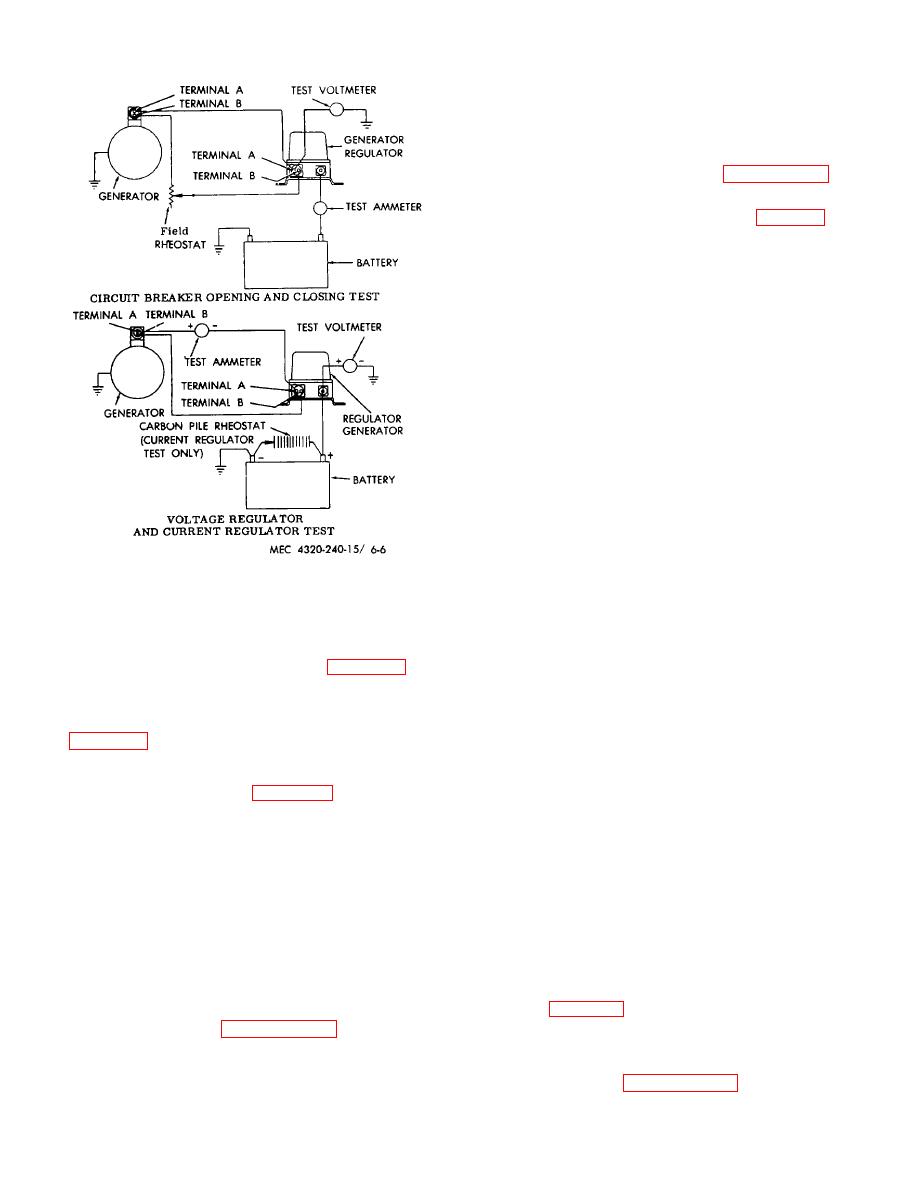

Figure 6-6. Generator regulate test set-up. |

|

||

| ||||||||||

|

|

b. Removal. Refer to figure 3-25 and remove the

magneto.

c. Cleaning and Inspection. Refer to paragraph 3-

46e and clean and inspect the magneto.

d. Disassembly.

Refer

to

and

disassemble the magneto.

e. Cleaning Inspection and Repair. (fig. 3-26)

(1) Clean the housing, gaskets, and

preformed packing, and distributor block with a wet

soapy cloth. Rinse and wipe dry.

(2) Clean all metal parts except bearings in

an approved cleaning solvent; dry with clean, dry

compressed air.

(3) Clean bearings by placing in a strainer

and dipping in a clean solution of cleaning solvent.

Flush until clean.

Caution

Do not spin balls or needles when

bearings are without lubricant.

Keep bearings covered so dirt and

dust will not enter.

(4) Repack bearings with clean bearing

grease. Inspect bearings for smooth rotation without

Figure 6-6. Generator regulate test set-up.

rough or catchy spots. Inspect races, balls, and needles

for wear or damage. Replace damage bearings.

age. With the generator operating at approximately

(5) Clean the electrical parts with a cloth

3,000 rpm and the generator operating temperature,

dampened in an approved cleaning solvent.

note the operating voltage. It must be 27.5 to 29.5 volts

as indicated on the voltmeter. Refer to figure 6-4 and

(6) Inspect the electrical parts for corrosion,

adjust the voltage if necessary.

cracks, breaks, frayed insulation, damaged terminals, or

evidence of failures. Replace if damaged or defective.

(7) Connect the generator regulator as shown

(7) Inspect the spring for wear, cracks,

in figure 6-5 using the carbon pile rheostat. Check the

damage, or loss of tension; replace if damaged or

operating amperage of the current regulator. It should

deformed.

operate at 16 to 20 amperes. If it fails to operate within

the required range, refer to figure 6-4 and adjust the

(8) Inspect gear teeth for chips, breaks, wear,

current setting. After each change of adjustment,

or damage; replace if damaged.

(9) Test

the

on

a

standard

return to speed and read current.

condenser tester.

(8) If the adjustment cannot be made, replace

(10) Inspect all other parts for cracks, breaks,

the generator regulator.

wear, or other damage. Replace if damaged.

c. Replacement. Refer to figure 3-21 and replace

f. Assembly.

Assemble the magneto in the

the generator regulator.

reverse order of disassembly.

6-6. Magneto

g. Timing and Installation.

Time and install the

magneto (para 3-45g).

67. Radiator

description.

6-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |