|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

order of disassembly.

6-4. Starting Motor

a. General.

Refer

for

description.

b. Removal.

Refer to figure 3-22 and remove

starting motor.

c. Cleaning and Inspection. Refer to paragraph 3-

45e and clean and inspect the starting motor.

d. Testing. Connect the starting motor in a test

circuit as shown in figure 6-3. Adjust the starting motor

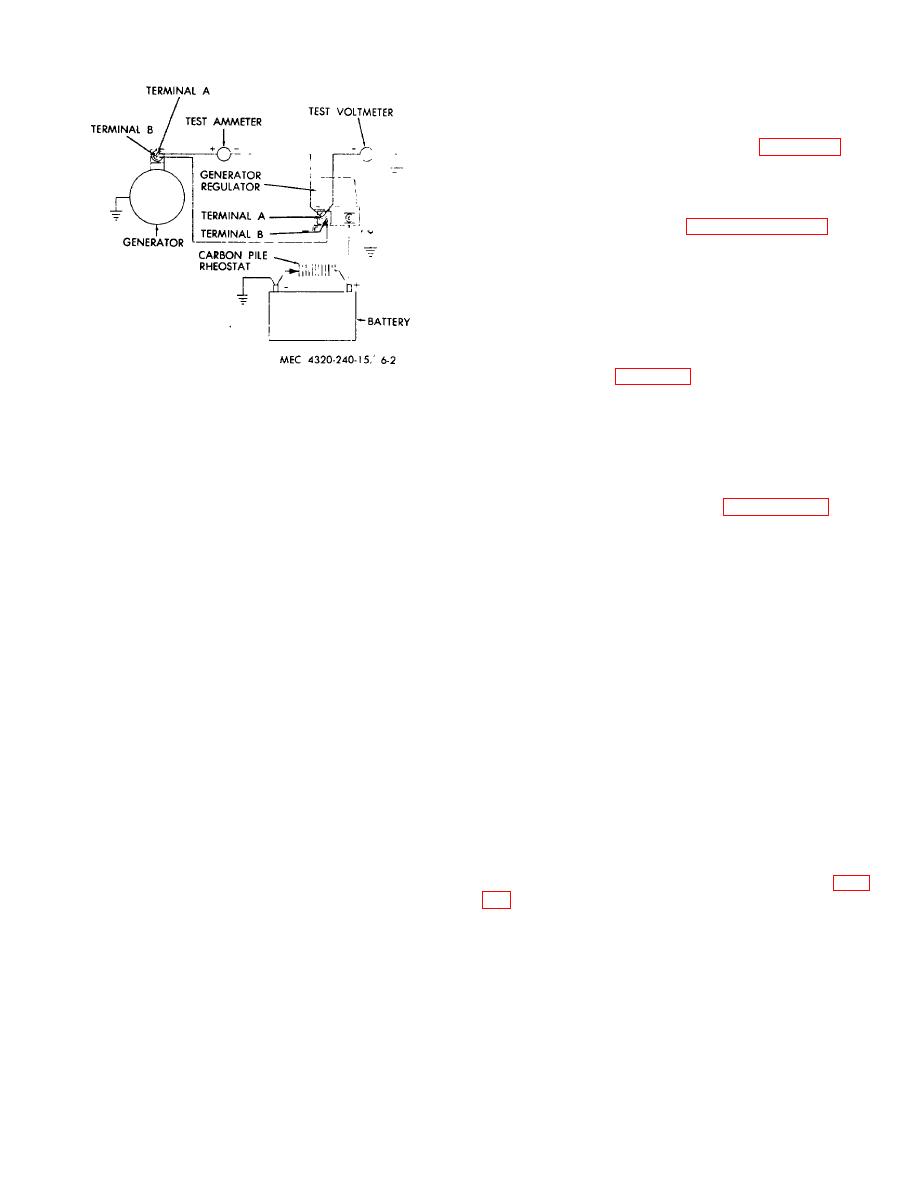

Figure 6-2. Generator test circuit.

voltage draw to 23.5 volts by adjusting the variable

resistance. With the starting motor operating with a

(7) Check for open circuits by inspecting for

voltage draw of 23.5 volts, the speed should be between

loose connections at the points where the conductors

5,800 and 6,800 rpm and the current draw should be 33

are connected to the commutator risers. Open circuits

amperes. If speed is not within limit or the current draw

can be checked electrically by determining if continuity

is not 33 amperes, repair or replace the motor.

exists between adjacent commutator bars. If the bars

e. Disassembly.

Refer to

and

are not badly burned, resolder the leads and turn the

disassemble the starting motor.

commutator down on a lathe. Undercut the mica and

test for short circuits as described in subparagraph (6)

f. Cleaning, Inspection, and Repair.

above. If the open circuit cannot be corrected replace

the armature.

(1) Clean the armature and field frame

(8) Check for grounds by checking the

assembly with a cloth lightly dampened in an approved

armature with a test lamp. Place one probe of the test

cleaning solvent.

lamp on the armature core and the other on each

(2) Clean all other parts of the starting motor,

commutator bar in turn. If the test lamp lights, the

except the brushes, in an approved cleaning solvent; dry

armature is grounded. If grounded, clean it thoroughly

thoroughly with compressed air.

and recheck for grounds. If ground cannot be corrected,

replace the armature.

(3) Check the size of the brushes; replace

them if they are less than 3/8 of an inch long.

(9) Check the field coils for grounds by

checking the coils with a test lamp. Place one probe of

(4) Inspect the armature commutator for

the test lamp on the field frame assembly and the other

roughness, out-of-round or high mica. If any of these

on the field coil leads. If the test lamp lights, the field

conditions exist, turn the commutator down on a lathe

coils are grounded. Replace the field coils if a ground is

and undercut the mica 1/32 inch. Remove only enough

indicated.

stock to make the commutator smooth and round. After

undercutting, finish the commutator with No.

00

(10) Check the field coils for open circuits by

sandpaper. Clean all particles off commutator using

checking with a test lamp. Connect the probes of the

compressed air. Check armature for short circuits (para

lamp to the two leads from the coils. If the lamp does

not light, the coil is open. Replace the field coils if the

circuit is open.

Caution

Always blow particles off the

commutator in the direction away

from the armature windings.

(5) Check the brush holders for distortion,

cracks, breaks, or other damage; replace damaged

brush holders.

6-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |