|

|||

|

|

|||

|

Page Title:

Operation Under Usual Conditions |

|

||

| ||||||||||

|

|

pump casing with liquid being pumped. Fill until liquid

(1) Increase or decrease the pumping rate of the

reaches the top of the casing. Reinstall the plug.

pump by varying the setting of the throttle. No other

control operation is necessary during operation.

Caution. Never operate the engine without first

priming the pump.

(2) Do not completely close any valves in the

discharge line. This will cause heating of the fluid in the

pump. Make sure that some passage of liquid continues

2-12. Stopping

through the pump during operation.

2-14. Operation in Extreme Cold (Below 0 )

F

b. Perform the daily preventive maintenance (para

a. General. Take special precautions and provide

36).

extra servicing necessary to maintain the operation of

2-13. Operation Under Usual Conditions

the pumping unit in subfreezing temperatures.

b. Fuel System. Keep the fuel tank as full as possible

to keep water in the air from condensing in the fuel tank.

b. After the engine has warmed up, pull out the

Service the fuel sediment bowl and fuel strainer daily

throttle (9, fig. 2-4), so that the engine operates at

(fig. 86).

governed speed (approx. 2,250 rpm).

c. Lubrication. Lubricate the pumping unit as directed

c. The pump should prime and pump within 5

in the lubrication order (LO 5-4820-240-12).

minutes. If the engine runs for more than 5 minutes

d. Coolant System. Maintain a proper amount of

without pumping, there is probably a mechanical defect.

antifreeze in the engine coolant. Refer to table 2-1 for

Shut down the pump engine; check for leaks in the

the correct antifreeze mixture.

Before installing

suction lines and check for other defects.

antifreeze, clean and flush the coolant system as

d. Maintain a check of the suction pressure gage and

directed in paragraph 8-52. Check carefully for coolant

the discharge pressure gage to assure that the pump is

leaks.

operating within normal capabilities.

e. Electrical System. Keep electrical components

e. Positioning of controls.

free of ice and moisture. Avoid unnecessary

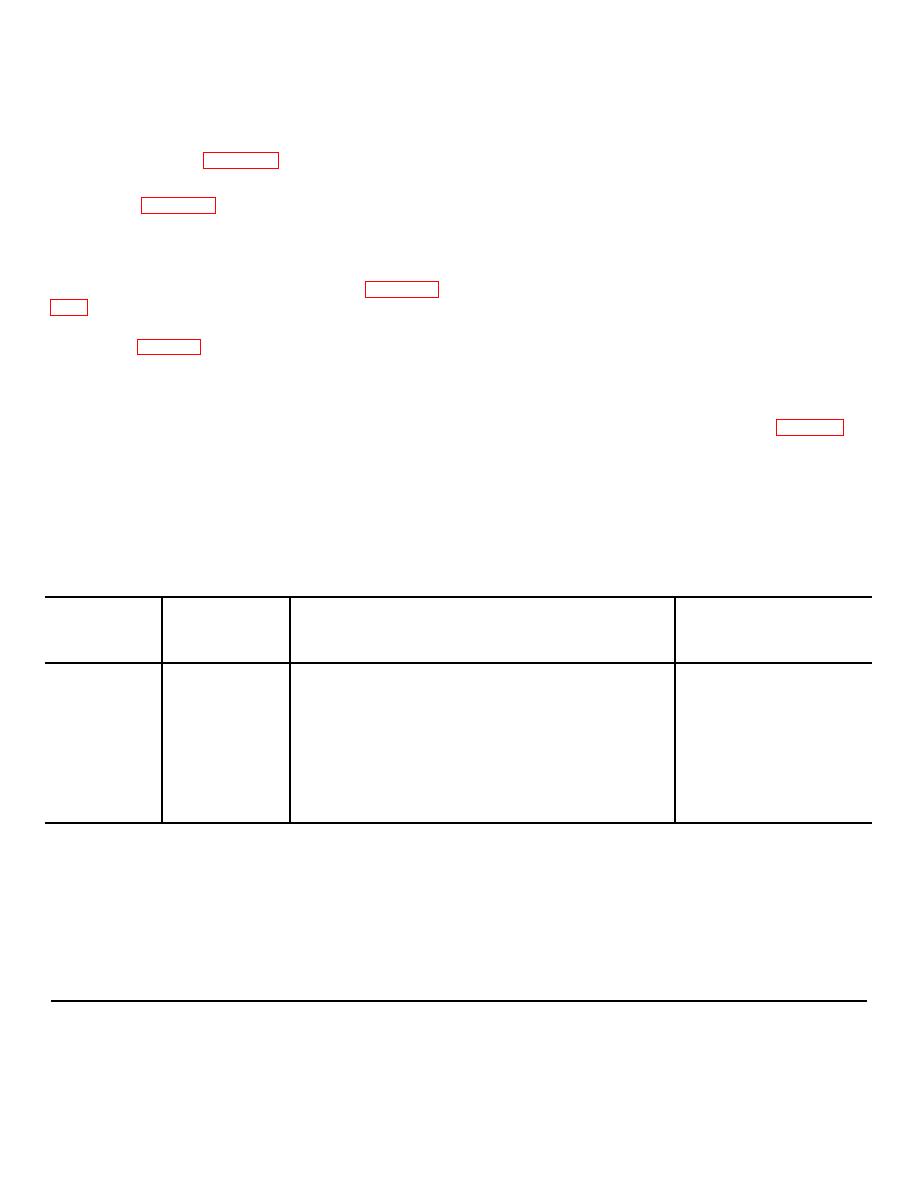

Table 2-1. Freezing Points, Composition, and Specific Gravities of Military Antifreeze Materials

Lowest

Pints of

Ethylene glycol

expected

inhibited

coolant solution

Compound antifreeze arctic2

ambient

glycol per

specific gravity

gal. Of coolant1

at 68 3

temp.

F

F

+20

1

1.022

Issued full strength and ready mixed for 0 to -65 F

+10

2

temperatures for both initial installation and replenish-

1.086

0

2

ment of losses.

1.047

-10

3

1.055

-20

3

1.062

-30

4

1.067

-40

4

1.078

-50

Arctic anti-

DO NOT DILUTE WITH WATER OR ANY OTHER

-60

freeze pre-

SUBSTANCE

-75

ferred

1

Maximum protection is obtained at 60 percent by volume (4.8 pints of ethylene glycol per gallon of solution).

2

Military Specifications MIL-C-11755 Arctic type, nonvolatile antifreeze compound is intended for use in the cooling

system of liquid-cooled internal combustion engines. It is used for protection against freezing primarily in Arctic regions

where the ambient temperature remains for extended periods close to -40F or drops below, to as low as -90 F.

3

Use an accurate hydrometer. To test hydrometer, use 1 part ethylene glycol antifreeze to 2 parts water. This should

produce a hydrometer reading of 0 F.

Note. Fasten a tag near the radiator filler cap indicating the type antifreeze.

2-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |