|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

T M 5-4320-237-15

other damage.

(7) Inspect all other parts for cracks, dis-

(4) Inspect the governor thrust sleeve

tortion, wear, and other damage; re-

for cracks, wear, and scoring.

place all damaged parts.

(5) Inspect the governor flyweights for

c. Reassembly and Installation.

worn mounting holes and for worn

(1) Reassemble the camshaft and gover-

-

t h r u s t pins.

nor in reverse of the numerical se-

(6) Inspect the governor yoke and shaft

quence as illustrated in figure 47.

for a worn shaft and yoke, bent

shaft, and worn or damaged threads.

(2) Install the crankshaft (para 98).

Section VII. CRANKCASE

101. General

102. Crankcase

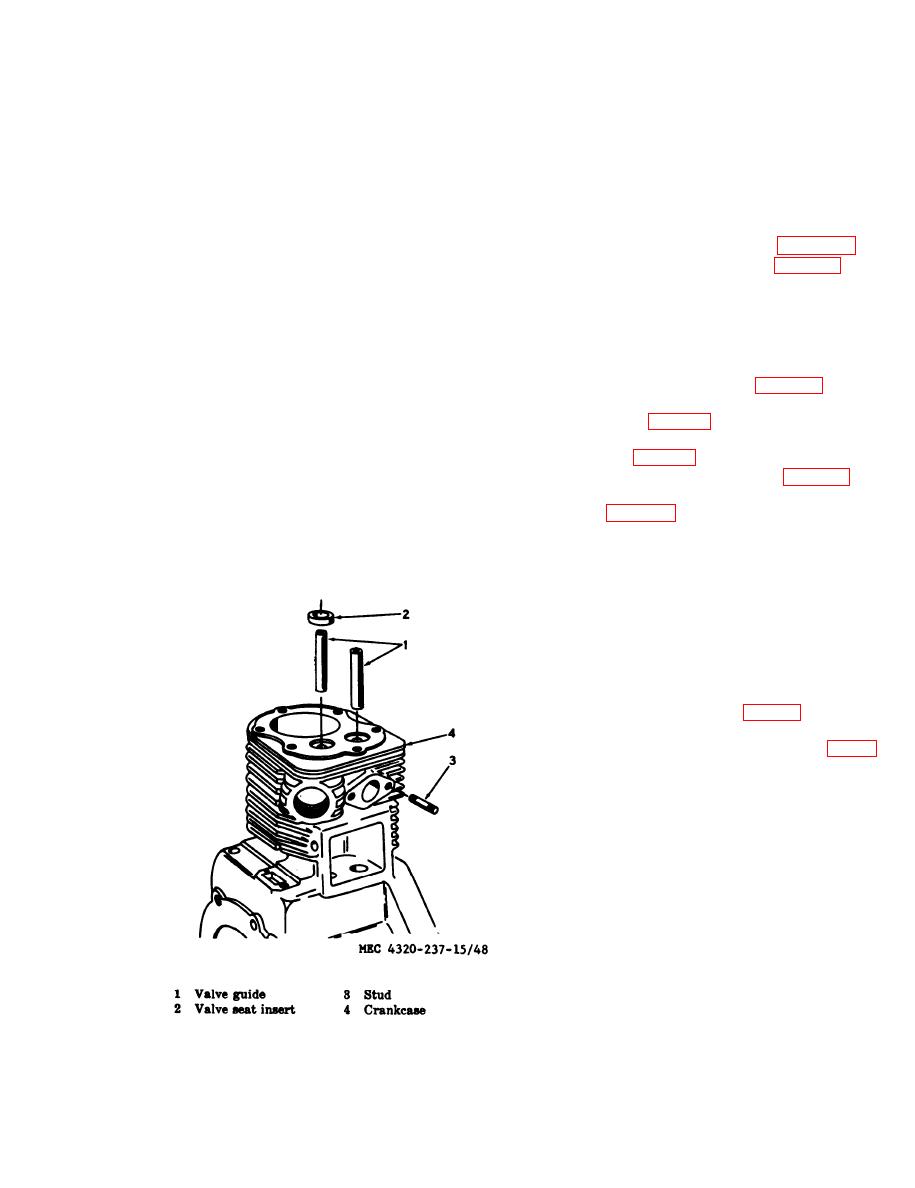

The crankcase is an integral unit which in-

a. Removal.

eludes the cylinder block and the crankshaft

(1) Remove the valves (para 92).

housing. The cylinder block portion of the

(2) Remove the engine base and oil

unit is deeply finned to promote mm-e rapid

pump (para 94).

dissipation of the heat generated during the

(3) Remove the piston and connecting

operation of the engine. The crankcase is pro-

rod (para 96).

vided with valve guides which are pressed in-

(4) Remove the crankshaft (para 98).

(5) Remove the camshaft and governor

insert is peened into the crankcase.

b. Cleaning and Inspection.

(1) Clean the crankcase with an approved

cleaning solvent; dry thoroughly.

(2) Inspect the cylinder bore for cracks,

warping, worn or scored cylinder

walls, broken cooling fins, worn or

damaged threads, and other damage.

Replace a damaged crankcase.

(3) Check the fit of the valves in the

valve guides. If it is not within the

tolerances listed in table 1, drive out

the valve guides and replace them

with new guides as shown in figure

48.

(4) Check the exhaust valve seat insert

for distortion, cracks, looseness, and

pitting. If necessary, replace the in-

sert as follows:

(a) Use a puller to remove the insert

from the exhaust valve opening.

(b) Clean all carbon out of the insert

counterbore in the cylinder block.

and clean the valve stem guide bore.

(c) Finish the counterbore in the cylin-

der block to provide the correct

bore-to-insert clearance. Chill the

insert with dry ice and, using a pi-

lot driver, tap the insert into place

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |