|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4320-234-12

of solvent is 100 to 138F (38 to 59

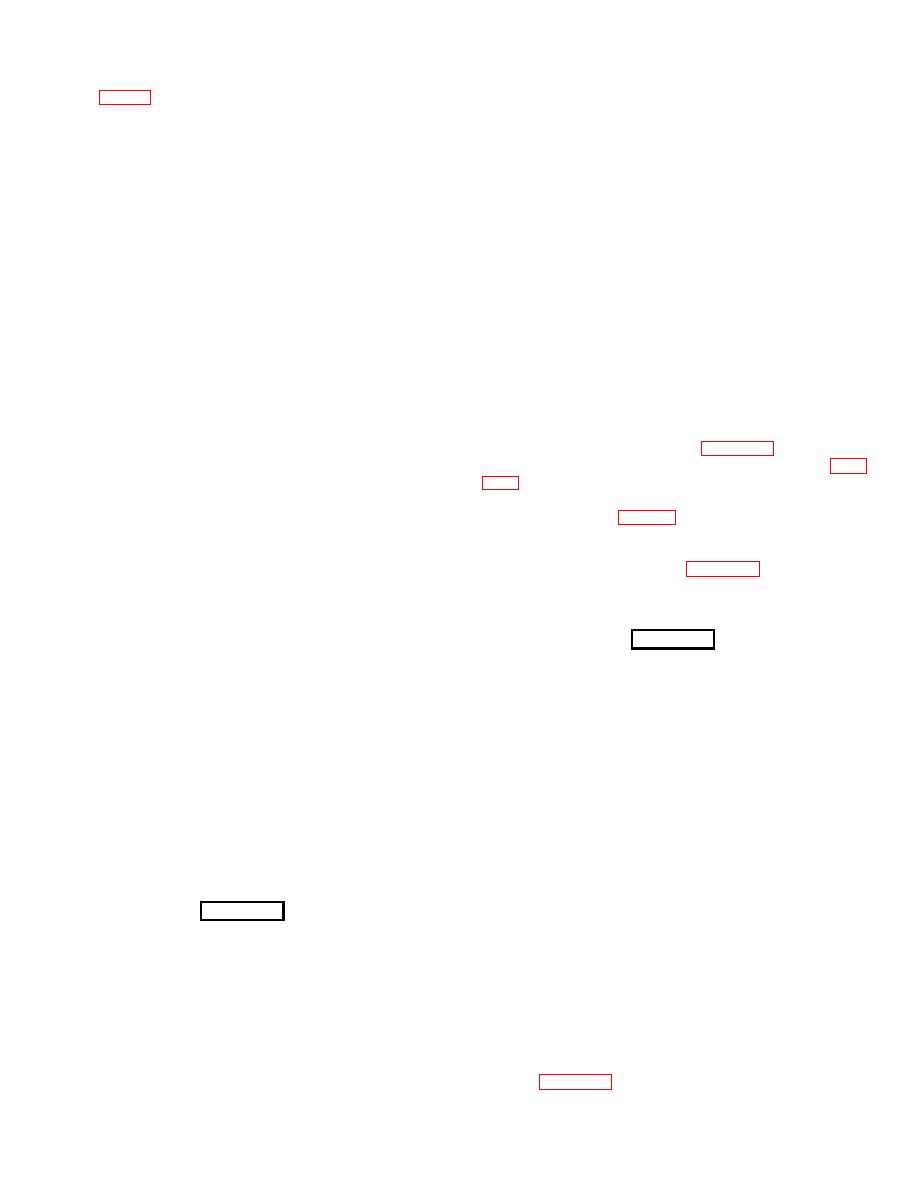

KEY to fig. 4-6:

C).

1. Engine side panel

2. Screw

3. Nut

4. lock washer

brush. Wipe with a cloth dampened with dry cleaning

5. Crank clip

solvent (fed. spec. P-D-680).

6. Screw

(2) Clean all remaining parts with an approved

7. Flat washer

cleaning solvent.

8. Screw

(3) Inspect the muffler for cracks, holes, severe

9. Flat washer

rust, and other damage; replace a damaged muffler.

10. Top hood

11. Screw

(4) Inspect the remaining parts for cracks,

12. Flat washer

distortion, and other damage; replace damaged parts.

13. Screw

14. Flat washer

c. Reassembly. Reassembly of the muffler and

15. Lower left panel

piping is the reverse of disassembly. Refer to figure 4-

16. Cap screw

5.

17. Nut

18. Lock washer

4-19. Engine Housing

19. Battery charging receptacle

20. Screw

a.Removal

21. Flat washer

22. Screw

(1) Remove the air cleaner (para 4-17).

23. Flat washer

(2) Remove the muffler and exhaust system (para

24. Lower right panel

25. Engine crank

(3) To remove the lower left and lower right side

26. Screw

panels (15 and 24, fig. 4-6), disconnect the drain lines

27. lock washer

from the connections on the panels.

28. Radiator grille

(4) Disassemble the engine housing following the

29. Baffle

sequence of index numbers in figure 4-6.

30. Baffle

31. Baffle

b.Cleaning and Inspection.

32. Baffle

33. Rear panel

34. Nut

WARNING

35. Lock washer

Clean all parts in a well-ventilated

36. Flat washer

area. Avoid inhalation of solvent

37. Cap screw

fumes and prolonged exposure of

38. Hasp

skin to cleaning solvent.

Wash

39. Snap

exposed skin thoroughly.

Dry

40. S-hook

cleaning solvent (fed. spec. P-D-

41. Chain

680) used to clean parts is potentially

42. Cap screw

43. Nut

dangerous

to

personnel

and

44. Lock washer

property. Do not use near open

45. Flat washer

flame or excessive heat. Flash point

46. Stone shield

of solvent is 100 o to 138 F (38 to 59

47. Radiator shell

C).

b. Cleaning and Inspection.

(1) Clean the parts of the engine housing with a

cloth dampened with dry cleaning solvent (fed. spec.

WARNING

P-D-680); dry thoroughly.

Clean all parts in a well-ventilated

area. Avoid inhalation of solvent

(2) Inspect all parts for rust, corrosion, cracks,

fumes and prolonged exposure of

chipped paint, dents, and distortion. Straighten dented

skin to cleaning solvent.

Wash

and distorted panels. Remove rust and corrosion with

exposed skin thoroughly.

Dry

sandpaper, rubbing until the surface is clean and bright.

cleaning solvent (fed. spec. P-D-

Prime and paint the bare surfaces.

680) used to clean parts is potentially

dangerous

to

personnel

and

c.Installation. Installation is the reverse of removal.

property. Do not use near open

Refer to figure 4-6.

flame or excessive heat. Flash point

4-15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |