|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

suction lift in excess of 25 feet.

(3) The suction line should be as large a

diameter and as short as practical, and should be

installed with as few bends as possible. Use no fittings

of less than a 6-inch diameter.

(4) The highest point in the suction line should

be at the pump, and the line should be laid in a decline

from the pump to the source. Avoid high points which

will form air pockets.

(5) Make sure that connections in the suction

line are air tight. Even a small leak will greatly reduce

pumping efficiency and may cause difficulty in priming.

(6) Support the suction line at or near the pump

to prevent strain.

d. Install the discharge line on the discharge elbow

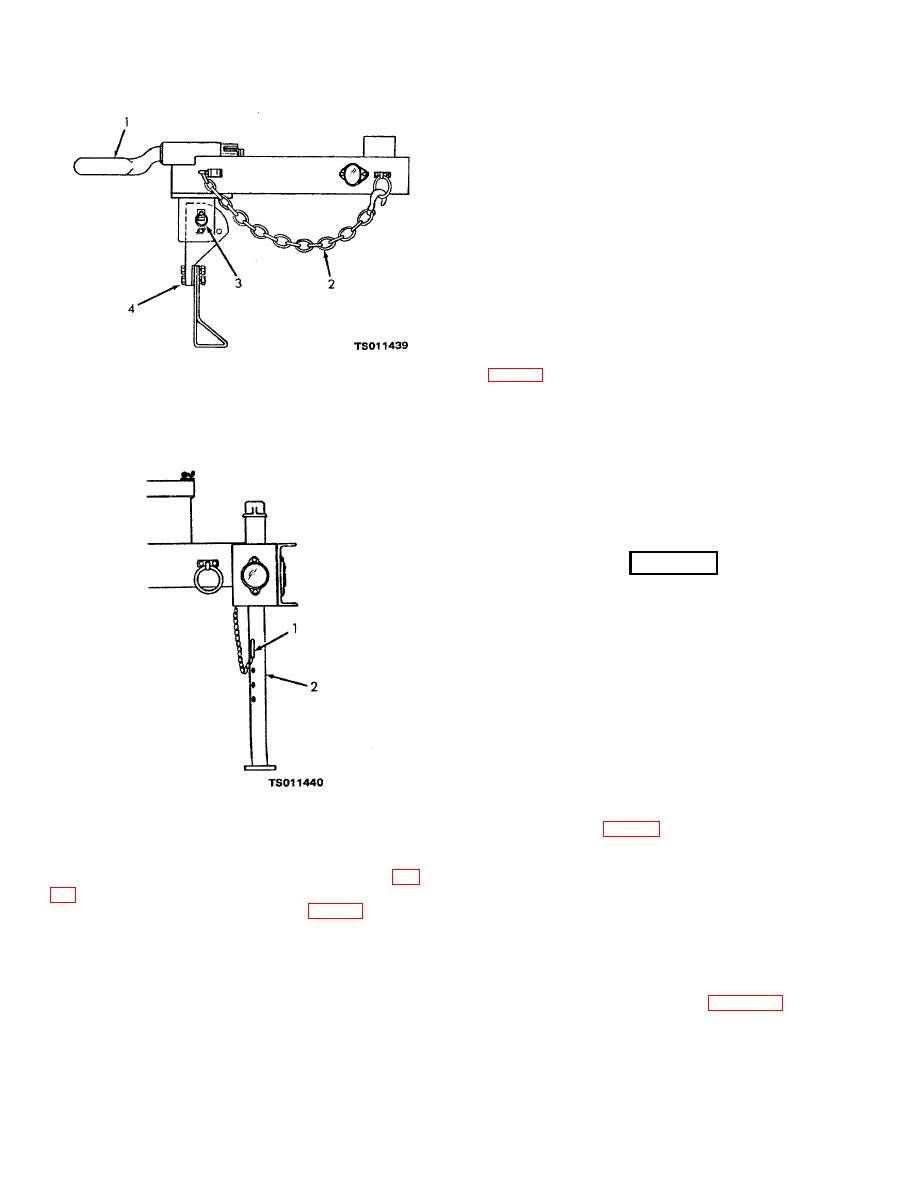

1. Tow bar

3. Lock pin

(fig. 1-1) as follows:

2. Safety chain

4. Front leg assembly

(1) Remove the threaded cap from the

discharge port. The discharge port has a 6-inch NPT

Figure 4-1. Front chassis leg.

female thread. Connect it to a discharge line with a

matching 6-inch thread.

(2) Avoid unnecessary fittings in the discharge

line. When necessary to use elbows, use long radius

type to reduce friction loss.

(3) Support the discharge line at or near the

pump to prevent strain.

WARNING

Do not operate the pump unit in an

enclosed area unless exhaust gases

are piped to the outside. Inhalation

of exhaust fumes will result in

serious illness or death.

e. If the centrifugal pump is operated indoors, you

must provide piping to carry exhaust gases to the

outside of the building. Make sure that the diameter of

the exhaust piping is large enough to prevent excessive

back pressure in the engine.

f. If an auxiliary fuel supply is to be used, connect a

1. Lock pin

2. Rear leg

fuel line between the source of supply, the auxiliary fuel

line connector (6, fig. 2-2), and the 3-way fuel source

Figure 4-2. Rear chassis stand.

selector valve (5) on the fuel tank. Operate the fuel

valve to the AUX position.

1-1), as follows:

NOTE

(1) Remove the threaded cap (fig. 1-1) from the

Due to the engine heat and vibration, engine

suction port. The suction port has a 6-inch NPT female

cylinder head bolts have a tendency to loosen at

thread. Connect it to a suction line with a matching 6-

initial operation. After the first 50 hours of

inch NPT thread.

engine use, retighten the cylinder head bolts to

(2) Keep the suction line as short as possible

a torque of 35 to 40 foot-pounds. Follow the

and the suction lift as low as possible. Reduction in

tightening sequence shown in figure 4-3.

pumping capacity becomes noticeable at suction lifts in

excess of 15 feet and is very pronounced at 25 feet.

You should not attempt to operate the pump with a

4-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |