|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

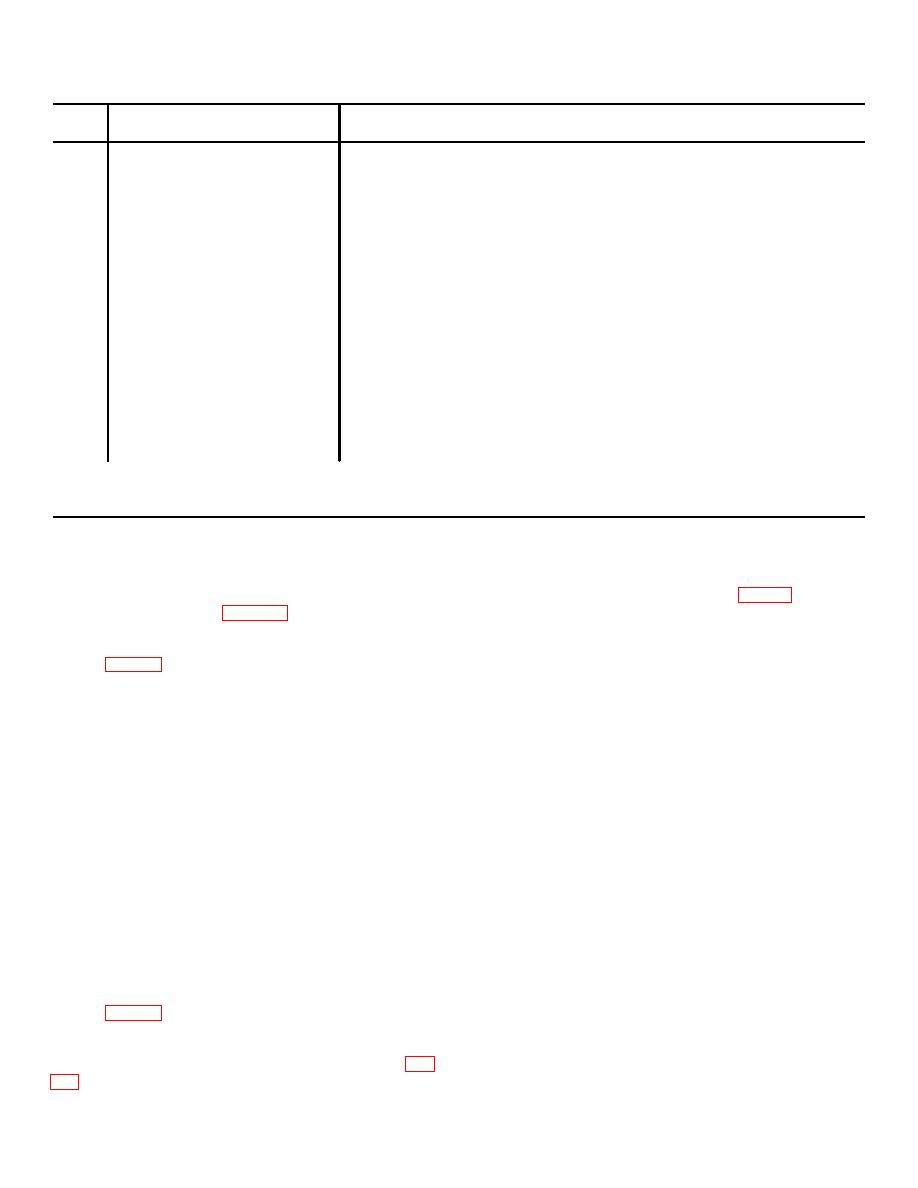

TM 5-4320-234-12

Fig. &

index No.

Name

Operation and use

2-1 13

Battery disconnect switch

In the ON position, the battery disconnect switch closes circuits to the starting

system and ignition switch. In the OFF position, it interrupts these circuits.

2-1 14

Ignition switch

In the ON position, the ignition switch energizes the oil pressure and water

temperature gage circuits and removes the ground from the ignition circuit to

permit engine ignition. Battery disconnect switch must be in ON position to

make this switch operative. When moved to OFF, ignition switch stops the

engine by grounding the magneto, regardless of the position of battery

disconnect switch.

2-1 15

Safety bypass switch

When reset, the safety bypass switch causes an electrical bypass of the oil

pressure safety switch to allow normal starting.

2-2 1

Air cleaner restriction indicator

Indicates red when air cleaner is clogged, preventing free air passage. Requires

reset after air cleaner service.

2-2 2

Fill plug

Allows pump body to be filled with fluid during priming. Replace plug before

starting.

2-2 3

Suction gage valve

When open, the suction gage valve applies suction port pressure to suction gage.

2-2 4

Discharge pressure gage valve

When open, the discharge pressure gage valve applies discharge pressure to

discharge pressure gage.

2-2 5

3-way fuel source selector valve

This valve has three positions as follows:

OFF position shuts off fuel supply to engine.

TANK position opens tank-to-engine fuel supply line.

AUX position opens the line between the auxiliary fuel supply and engine.

2-2 6

Auxiliary fuel line connector

Provides connection for fuel line when engine fuel is supplied from auxiliary

source of supply.

2-3 1

Fuel tank level gage

Indicates level of fuel in fuel tank.

2-3 2

Fuel tank filler cap

Remove filler cap to fill fuel tank.

2-3. Starting

c. Starting Procedures.

a. Preparation for Starting.

(1) Push in throttle control (5, fig. 2-1) half way.

(1) Perform the necessary daily preventive

(2) Pull out choke control (8) all the way.

maintenance procedures (para 3-6).

WARNING

(2) If the pump is being started for the first time,

or if it has been drained since its last use, remove the fill

Operation of this equipment presents a

plug (2, fig. 2-2) and fill the pump body with the fluid to

noise hazard to personnel in the area.

be pumped. Replace the fill plug.

The noise level exceeds the allowable

CAUTION

limits for unprotected personnel. Wear

ear muffs, or wear ear plugs fitted by a

Be sure the pump has fluid in it before

trained professional.

you attempt to start it. Starting the

(3) Turn battery disconnect switch (13) to ON.

pump when it is completely dry may

Turn ignition switch (14) to ON.

damage the shaft seal.

CAUTION

Unlatch and pull down the stone

shield to provide adequate air flow

Excessive cranking will cause the

through the radiator.

starting motor to overheat. If engine

(3) Remove side panels from the engine.

fails to start after 30 seconds of

NOTE

cranking, release the starter button and

wait 2 minutes for the starting motor to

During operation, it may be necessary

cool before attempting to start the

to reinstall the engine side panels,

engine again.

depending

upon

the

ambient

(4) Press to reset the safety bypass switch (15).

temperature,

to

maintain

engine

operation within the 180 to 200F

Press and hold the starter pushbutton (12). The engine

should start after a few revolutions of the crankshaft. If

range.

b. Fuel Supply.

it does not start within 30 seconds, release the

pushbutton to stop cranking.

(1) Check the fuel level on the fuel tank level

(5) When engine starts, release starter push

gage (1, fig. 2-3) mounted in the top of the tank. Refill if

button and watch the oil pressure gage (7). If normal

the gage reads low or empty unless auxiliary fuel supply

operating range is not achieved within 10 seconds, shut

is to be used.

down the engine.

(2) Move the fuel source selector valve (5, fig.

(6) Push in the choke control (8) as necessary

2-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |