|

| |

APPENDIX A

INSTALLATION

The following information is general in nature and is

presented as a guide to the installer and serviceman.

1.

The meter should be mounted on a suitable

base or platform so it will not be supported by

the piping, except vertical meters which are

supported directly by the piping. Dimensional

outline drawings showing size and location of

anchor holes are available for all meters.

2.

When possible, install the meter so that it

cannot be accidentally drained of product,

however, it is advisable to drain the meter of

water

and

sediment

periodically.

When

installing a meter, be sure drain plug is

accessible.

3.

Piping should not produce an undue strain on

the meter.

4.

Protect the meter and system against the

effects of thermal expansion with an adequate

relief valve.

5.

Where necessary, a deaerator or air eliminator

should be installed to keep air and vapor out of

the meter.

6.

Remove the inner mechanism if the system

is to be pressure tested with water.

7.

All piping should be internally clean before

meter is put into operation. Rust, dirt, welding

shot and other foreign material should not be

present. It is best to remove the inner

mechanism and flush the lines. This will

prevent damaging the metering element. The

meter should be protected by a strainer.

8.

Do not calibrate with water or allow water to

stand in the meter. Flush meter with a light

lubricating oil if it is left idle or stored.

9.

Unless otherwise specified, meters normally

flow from left to right when viewing from the

flanged side of the housing. Most meters can

be changed to flow from right to left, see

REVERSING SECTION.

10.

A counter may be located in any one of four 90

positions. Large numeral counters may be

located in any of eight 45 positions.

OPERATION

START-UP

It is best to fill the meter by gravity. However,

where hydraulic conditions require that the pump(s)

be operated, extreme care should be used in

opening the valves at the meter. In all instances,

the air should be evacuated slowly from the meter

and system.

1. Establish product flow through meter .

With outlet valve closed, slowly open inlet

valve. Slowly open outlet valve until counter

begins to turn. Leave outlet valve in throttled

position until air is evacuated from meter. This

is necessary to protect meter from excessive

speeds due to air in lines of system.

2.

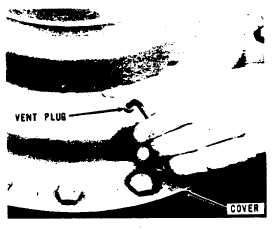

Loosen vent plug when meter is filled with

liquid, Fig. 3 (On meters so equipped).

Permit the air trapped in the meter cover to

escape through the threads. Close plug when

product begins to seep through the threads.

FIGURE 3 - LOOSENING VENT PLUG

3.

To fully open inlet and outlet valves, open

valves slowly, pausing if register operation is

rough. Continue opening when operation

becomes smooth.

A9-35

|