|

|||

|

|

|||

|

Page Title:

Section III. ORGANIZATIONAL MAINTENANCE |

|

||

| ||||||||||

|

|

TM 10-7200-200-13

Section Ill. ORGANIZATIONAL MAINTENANCE

4-6. Special Tools and Equipment

The five gallon water can does not require special

tools, parts, or equipment.

4-7. Repair

are in good condition. Replace missing or defective

gaskets with new ones. Use only the approved

nontoxic cement (FSN 8040-273-8717).

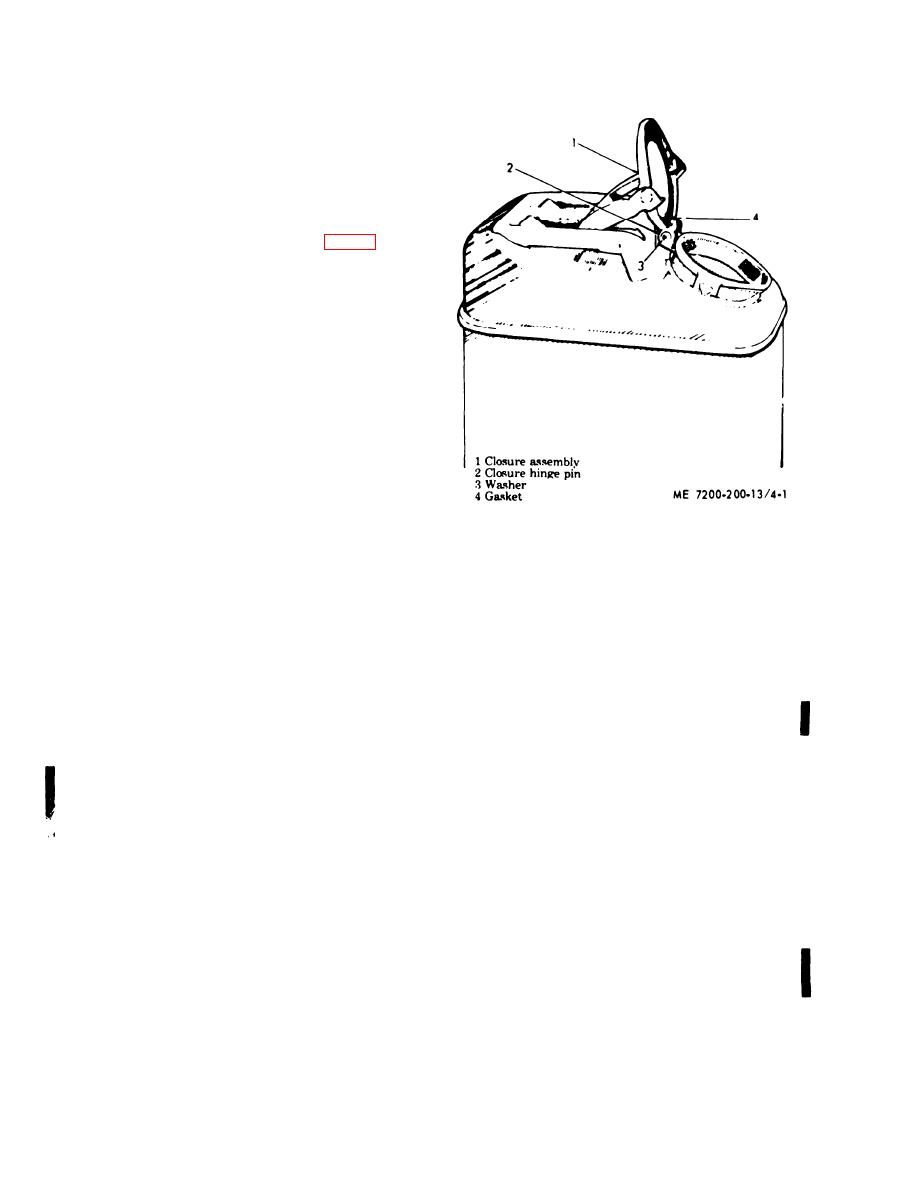

b. Closure Assembly Replace the closure assembly

(1) when damaged.

c. Replace damaged or worn pin (2) and washer (3).

Use a hammer to peen replacement hinge pin while

holding opposite end of pin in position with another

hammer or suitable tool.

Figure 4-1. Water can, (aluminum, 5-gallon.

Section IV. DIRECT SUPPORT MAINTENANCE

removed. Rinse cans in clean boiling water, turn

4-8. Repair Parts, Special Tools and Equip-

upside down, and allow to dry.

ment

d. Rinsing and Drying. Rinse cans in clean boiling

a. Special Tools and Equipment. The five gallon

water. Turn upside down to dry.

water can does not require special tools and

e. Replacing Parts. Install new gasket and replace

equipment.

closure assembly, pin, and washer when parts are

b. Repair Pants. Repair parts issued with or

worn or damaged.

authorized for the five gallon gasoline can are listed

f. Leak Testing. Before the cans are painted they

in the Repair Parts List, Section VI.

will be tested for leaks. Cans with leaks in the body of

4-9. Refinishing

the can will be scrapped. The presence of leaks can be

determined by either of the following tests:

a. Removing Dents. No attempt will be made to

(1) Water tank test. Cans are subjected to internal

remove dents from cans. Dents in cans are accepta-

air pressure and completely submerged in clean

ble providing the cans are not ruptured and do not

water. Air bubbles emitted from cans indicate the

repair stacking.

presence and location of leaks.

b. Cleaning Exterior. Flanges and plugs, especially

(2) Air pressure test. Cans are subjected to

threads and gasket seats, must be thoroughly

internal air pressure of 7-to 9-psi for a period of 45

cleaned. Clean flanges and plugs and remove all

seconds. A drop in air pressure, as indicated in an

corrosion and other foreign matter. All gaskets

accurate pressure gage during the test period, shows

should be removed before cans are cleaned. All loose

the presence of leaks.

paint,. grease, and other foreign matter will be

removed from the exterior of the can. This can be

g. Repairing Leaky Cans. Cans with leaks in the

done by chemical or mechanical means.

body of the can will be scrapped, closure assembly .

c. Cleaning Interior. Cans will be thoroughly

leaks will be repaired.

h. Painting Exterior. After cans have been

cleaned by washing in hot water containing a

repaired, thoroughly cleaned, leak tested, and dried,

hand-dishwashing compound, P-D410. Repeat this

exteriors will be painted with enamel, TT-E-529.

until all loose scale or other foreign matter is

4-2 Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |