|

|||

|

|

|||

|

Page Title:

Section V. MAINTENANCE ALLOCATION CHART (PART 1) |

|

||

| ||||||||||

|

|

TM 10-7200-200-13

mechanically, it should be free of excessive grease

bly should be replaced as necessary.

and oil. Mechanical cleaning methods may include

f. Leak Testing. Before the cans are painted or

buffing or blasting. Buffing consistsof cleaning bqy

treated with preservative oil, they will be tested for

means of rotating brushes or rotating the can

leaks. Cans with leaks in the body of the can will be

against con verging brushes. Blasting consists of

scrapped. The presence of leaks can be determined

pressure spray ing the can with sand or grit or similar

by either of the following tests:

material. The operator must determine the extent to

(1) Water tank test. Cans are subjected to internal

which blasting is feasible without excessive metal

air pressure and completely submerged in clean

removal.

water. Air bubbles emitted from cans indicate the

c. Cleaning Interior. Before cans undergo further

presence and location of leaks.

reconditioning, clogged vent tubes will be cleaned by

(2) Air pressurre test. Cans are subjected to

prodding or by applying air pressure. Unlined cans

internal air pressure of 7-to 9-psi for a period of 45

will be thoroughly cleaned by washing with a strong,

seconds. A drop in air pressure, as indicated on an

hot, alkali solution or a suitable detergent solution.

accurate pressure gage during the test period, shows

This process will be continued until all loose rust,

the presence of leaks.

scale, or other foreign matter is removed. If the cans

are lined and the interior coating is broken, blistered,

g. Repairing Leaky Can. Cans with leaks in the

or loose, the interior linings must be stripped

body will be scrapped. Closure assembly leaks will be

repaired.

chemically and the cans must be cleaned thoroughly.

h. Painting Exterior. After cans have been

If more than very light rust remains after cleaning of

either lined or unlined cans, the rust should be

repaired, thoroughly cleaned, leak tested, dried, and

removed with solutions containing dilute phosphoric

rust freed, exteriors will be painted with one coat of

rust-inhibiting enamel. Before cans are painted,

acid.

d. Rinsing and Drying. Each can will be ade-

plugs must be inserted and hand tightened. Paint

will be applied uniformly by spray. Cans will be either

quately rinsed to remove cleaning solutions. Clean

hot water, maintained at a temperature of 150F. will

heated to a temperature of 250F and dried in a

suitable drying oven immediately after painting, or

be used for rinsing. After the can is rinsed, it will be

baked at 250 F for 45 minutes or an equivalent

siphoned free of excess water and heated for a period

time-temperature cycle.

sufficient to vaporize all remaining moisture. The

i. Prpreventing Interior rust. When cans have cooled,

can will be purged with air, preferably hot, to

remove the plugs and spray the interior of each can

eliminate all excess vapor. It must be above room

with preservative oil injected under pressure for

temperature and free" of all moisture and residue at

the completion of drying. Completion of drying can be

complete atomizing. No excess spray will remain to

determined by a simple test. Hold a cool glass over

collect on the bottom. All plugs with gaskets in place,

should be made wrench tight immediately after

the can opening; if condensation forms on the glass,

preservative oil has been injected, All air lines used

the can is not sufficiently dry.

for spraying preservative oil will be suitable trapped

e. Replacing Parts. Plugs for cans should be fitted

to prevent condensate in the cans.

with new synthetic rubber gaskets. Closure assem-

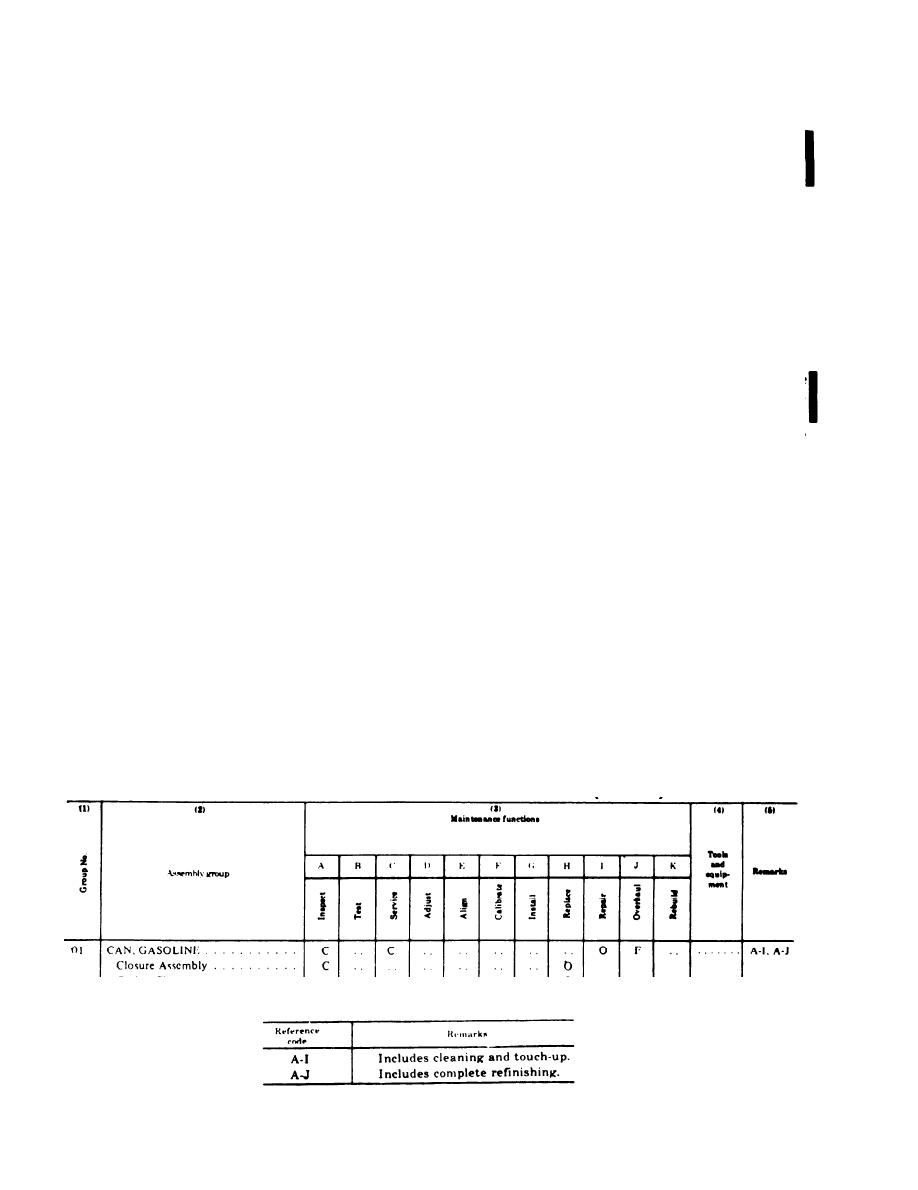

Section V. MAINTENANCE ALLOCATION CHART (PART 1)

Section V. REMARKS (PART II)

2-6

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |