|

| |

TM 10-4930-238-12&P

b.

Test.

(1)

(2)

(3)

Touch each probe of multimeter to opposite end hose coupling half. Use a multimeter and perform

a continuity test on the suction hose to insure the wires in the suction hose are not broken.

The resistance reading should be 5 ohms or less. Repair hose assembly if resistance is greater

than 5 ohms.

No hydrostatic testis required on the discharge hose and suction hose. If the local commander

requires a hydrostatic test, it is up to him as to how and when it is accomplished.

NOTE

Suction hose assembly should be tested every thirty days or whenever hose

has been damaged.

c.

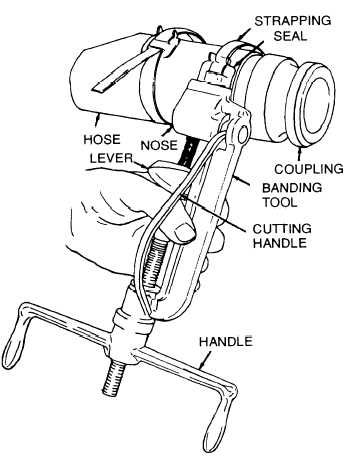

Repair. (Refer to Figure 4-4.)

(1)

Cut band and remove damaged coupling.

(2)

If hose is damaged within 1 foot (30.48 cm) of end of hose, cut strapping and remove coupling.

Figure 4-4. Hose Assembly Repair.

|