|

| |

TM 10-4320-348-14

Table 2-1. Operator Preventive Maintenance Checks For Pumping Unit. (Cont’d).

Location

Item

Item To

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

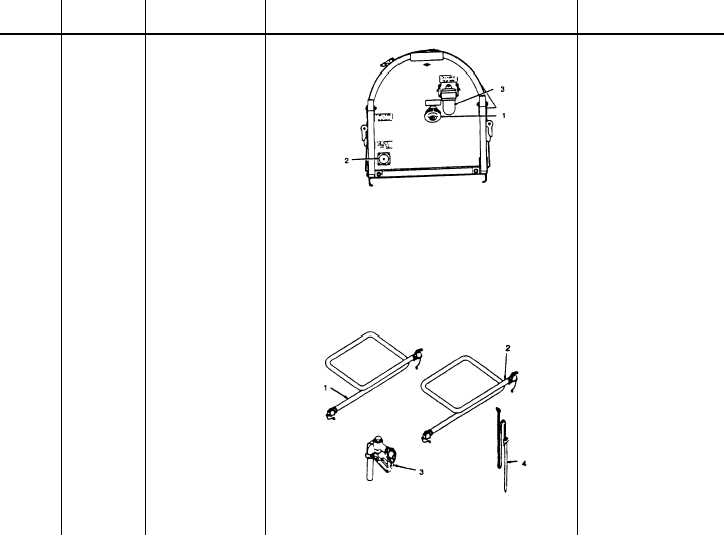

27

Before

Spark

Inspect spark arrestor (1) for carbon

Spark arrestor is dirty,

Arrestor

deposits or damage.

damaged, or missing.

28

Before

Electrical

Inspect electrical intervehicle connector (2)

Electrical intervehicle connector

Intervehicle

for damage.

is damaged or missing.

Connector

29

Before

Discharge

Inspect discharge coupling (3) and cap for

Discharge coupling and/or cap

Coupling

damage or gasket missing from cap.

is damaged or gasket is

missing.

Pumping

Assembly

Accessories

30

During

Suction Hose

Check suction hose assemblies (1) for

Cracks, abrasions, collapsed

Assemblies

evidence of leakage and collapsed walls.

walls or other damage is

Tighten loose connections.

detected.

2-14

|