|

| |

TM 10-4320-348-14

Table 2-1. Operator Preventive Maintenance Checks For Pumping Unit. (Cont’d).

Location

Item

Item To

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

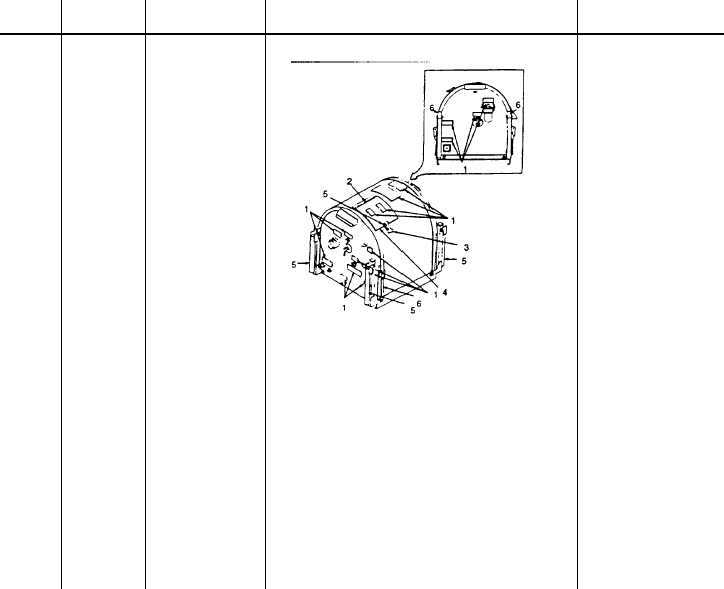

Sound

Enclosure

Exterior

4

Before

Coating

Check condition of coating. Coating shall

Cracks, abrasions, or other

be in good condition with no bare metal or

damage is detected.

corrosion.

5

Before

Information

Check that information plates (1) can be

Plates

read.

6

Before

Hinge, Latch,

Check that hinge (2), access door latch

Hardware cannot be secured.

and Door

(3), and door (4) ar: secure.

7

Before

Handles

Check condition of handles (5).

Handles are inoperable or bent.

8

Before

Ratchet Strap

Check condition of straps and ratchet

Strap is out or missing or

Assembly

assemblies (6).

ratchet is inoperable.

Sound

Enclosure

Interior

9

Before

Acoustical

Inspect acoustical foam within the

Acoustical foam blocks air flow,

Foam

enclosure. Check to make sure acoustical

contacts a hot surface, or is

foam does not block air flow, is not torn or

damaged.

scarred, and does not show signs of

contacting a hot surface.

2-8

|