|

| |

TM 10-4320-324-14

6-11.

Crankcase Repair (CONT).

(i) Measure each bore at points 1 and 2 in the vertical and horizontal positions "a" and "b".

(j) If recordings show that bearing tolerances are up to 0.001 inch (0.020 mm) maximum above value specified

above, crankcase is acceptable for further use as is.

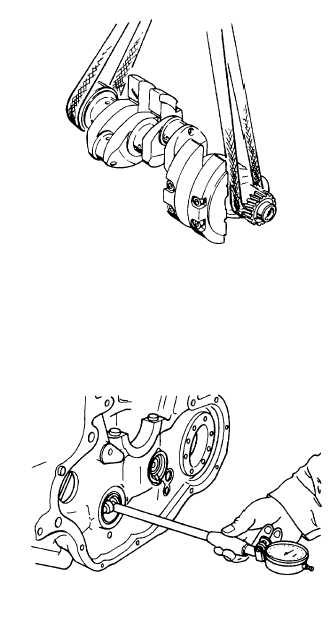

(5) Check bearing housing for alinement as follows:

(a) Coat main crankshaft journals with marking ink.

(b) Place crankshaft in crankcase and install bearing

caps according to the numbering. Torque bolts

according to Appendix F, Table F-1.

NOTE

If all bearings have a uniform contact pattern,

bearings are in alinement.

Do not bore out individual bearings.

(c) Rotate crankshaft and then remove it. If bearing

bores are in alinement there will be an even

pattern of marking by crankshaft in all bearing

bores. If bearing bores require alinement, the

bores must be line-bored at a machine shop.

(6) Check cylinder liner seating on crankcase Touch the

surface and feel for any evidence of roughness.

Seating surface must be level and free from

grooves. If cylinder liner seat must be reworked,

refer to Repair.

(7) Measure camshaft bearing bores of crankcase using

an inside dial indicator. Bore should be 1.889-

1.8911 in. (47.980-48.034 mm). If bores are

excessive, replace bearings using the procedure in

Repair.

6-48

|