|

| |

TM 10-4320-324-14

(2) Inspect cylinder head for external damage or

cracks. Replace cylinder head if damaged or

cracked.

(3) Inspect cylinder head parts for obvious

defects. Replace defective parts.

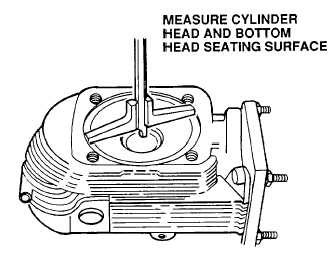

(4) Check cylinder head seating surface. It must

be flat and square. Slight damage to seating

surface can be removed by grinding cylinder

head on cylinder with fine abrasive paste. If

cylinder head seating surface is more

severely damaged, re-cut with cutting device.

NOTE

Measurement must be made with intermediate

ring inserted.

(5) After refacing cylinder head seating surface, measure clearance between cylinder head bottom and cylinder

head seating surface. The measured value may not be lower than 0.23 in. (5.8 mm).

(6) Using a micrometer, measure valve springs (4) length. Minimum length is 2.204 inch (56 mm). Replace if

less than minimum length.

(7) Inspect valve rotor and spring seat (5) for damage. Replace if damaged.

(8) Inspect valves (6 and 7) for cracks and pits. Replace as required. Reface valves if required and inspect to

the tolerances specified in Table 6-1.

6-37

|