|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-4220-202-15

roads, under all conditions of weather and

1-5. Identification and Tabulated Data

terrain.

a. Identitification. The Pumping Assembly

has three major identification plates. The in-

1-4. Components

formation contained on these plates is listed

a. Pump.

below.

(1) U.S. Plate. This plate is mounted

(1) Description of unit. The pump is a

on the top cover of the pumping assembly.

self-priming centrifugal, fuel dispensing pump.

It provides official nomenclature of the unit,

It is close-coupled to the engine by an inter-

model number, serial number, contract num-

m e d i a t e adapter the pump impeller being

ber, dimensions, cubage, weight, date inspected

mounted directly on the engine crankshaft. The

and date shipped.

suction inlet is provided with a swing check

valve to retain the liquid in the body of the

(2) Serial Number Plate. This plate is

pump when not in operation. The casing has

mounted on the pump-engine assembly. It pro-

a drain plug for completely emptying the

vides information regarding pump manufactur-

volute. There is a 1 1/2 inch priming plug

er, model number, serial number, Federal stock

for filling the separation chamber, volute and

number, type of drive and contract number.

s u c t i o n chamber to prime the pump. The

(3) Engine Plate. The engine plate is

suction inlet is on a horizontal position on the

mounted on the upper portion of the engine

side of the pump opposite the engine. The

shroud, on the pulley end of the engine. It

pump discharges through an opening in the

provides the model number, serial number,

top of the pump casing. Suction and discharge

size, rated speed, specification number, horse-

openings in the pump casing have 1 1/2 inch

power and manufacturing date. It also pro-

(International Pipe Standard) threads. The

vides engine operation and maintenance infor-

pump is coupled to the engine by an inter-

mation.

mediate casting, which incloses a mechanical

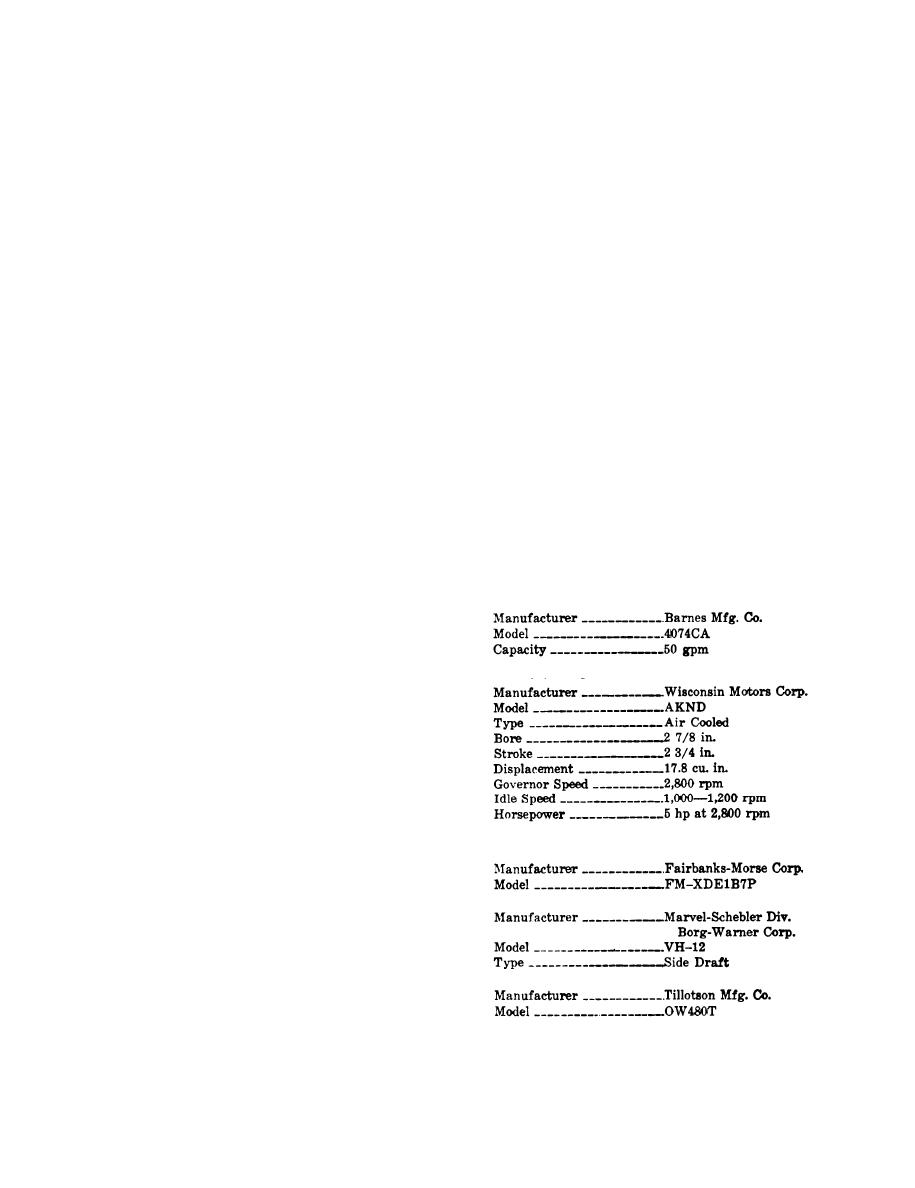

b. Tabulated Data.

seal on the crankshaft.

(1) Pumping assembly.

(2) Priming characteristics. The pump is

designed to prime in about 2 minutes when

the following conditions are present:

(2) Engine.

(a) A static suction lift of at least 5

feet.

(b) A 1 1/2 inch suction hose 50 feet

long.

(c) The impeller turning approximate-

ly 2,800 rpm. The pump is designed to deliver

n o t less than 22 pounds per square inch

pressure and not more than 27 psi at each

(3) Engine accessories.

nozzle discharge: provided two 50 foot lengths

(a) Magneto.

of 1 1/2 inch discharge hose are used in

parallel. Prevailing temperature of gasoline

being pumped should be between 50 and

(b) Carburetor.

60 F. When all the above conditions are pres-

ent, the pump should deliver 50 gpm.

b. Engine. The engine is a single cylinder,

air cooled, gasoline driven type capable of

(c) Fuel strainer.

d e v e l o p i n g about 5 horse power at 2,800

revolutions per minute (governed speed).

1-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |